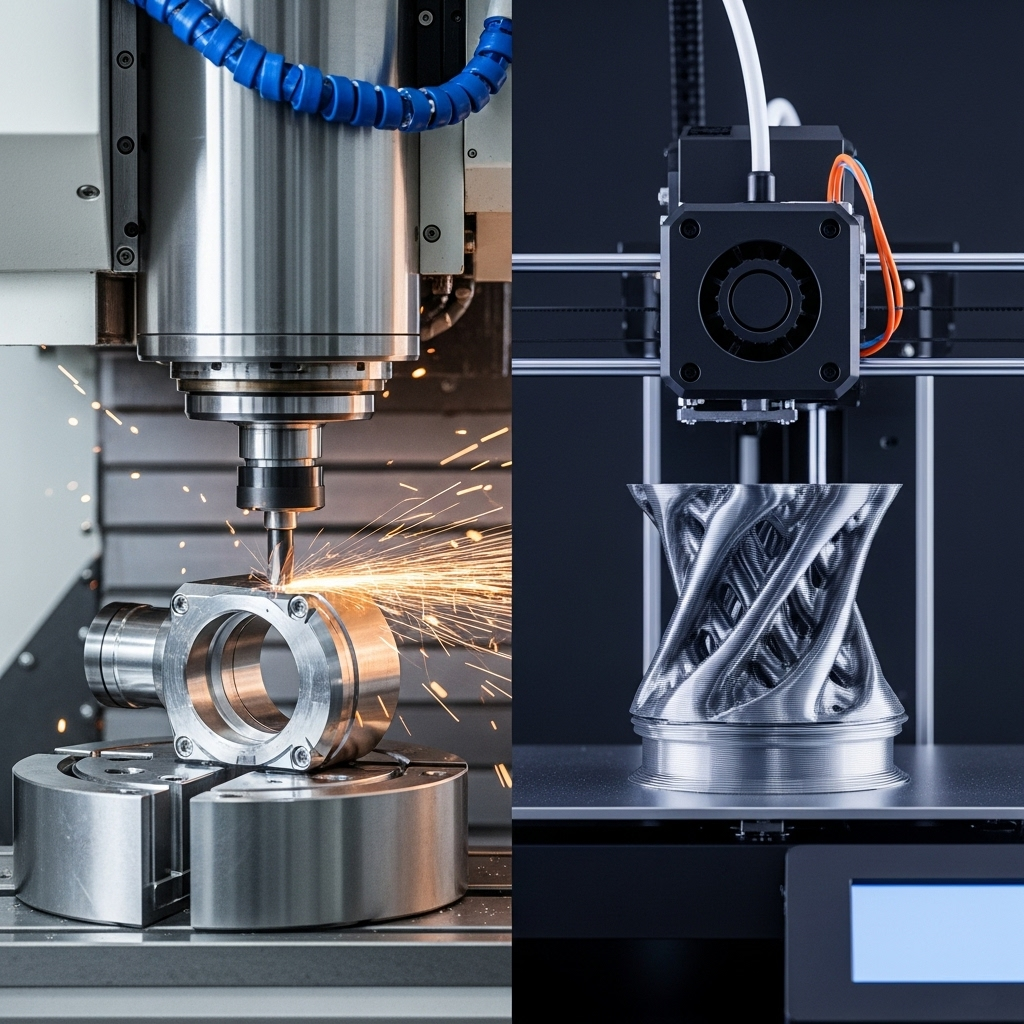

Subtractive vs. Additive – The Fundamental Difference

Traditional manufacturing methods are typically subtractive: a raw material block (e.g., a metal billet or plastic sheet) is shaped into the desired form through mechanical processes such as machining (milling, turning, drilling, grinding) or forming (stamping, bending). This often generates a significant amount of waste material, which must be disposed of or recycled. This results in material loss and increased costs, especially with expensive materials.

Additive manufacturing, on the other hand, builds parts layer by layer directly from a digital 3D model. Material is only applied where it is actually needed. This process significantly minimizes material consumption and leads to huge efficiency advantages, particularly with complex geometries. It not only reduces material costs but also lowers the ecological footprint of production.

Flexibility and Customization: The Strength of Additive Processes

Additive manufacturing enables cost-effective production of single parts or small series without the expensive and time-consuming process of mold or tool making. While injection molding requires a new specific tool for every new geometry (which can take weeks and cost six figures), 3D printing allows new parts to be generated and printed with just a few clicks in software. This eliminates lead times and drastically reduces fixed costs for small batches.

This flexibility allows for unprecedented design freedom and customization. Applications include medical technology (custom implants, prosthetics, or orthodontic devices), tailored machine components for specific uses, or individualized automotive interior parts. The ability to produce on-demand also reduces inventory costs and the need for large minimum order quantities.

Material Variety: Additive Manufacturing’s Catch-Up

Conventional methods have offered a vast range of processable metals, plastics, composites, and ceramics for decades—materials whose properties are extensively researched and standardized. 3D printing, however, is rapidly catching up. Today, a wide variety of materials are available—from polymers (e.g., ABS, PLA, Nylon, PEEK) to metal alloys (e.g., titanium, aluminum, stainless steel, nickel-based alloys) and high-performance ceramics (e.g., zirconia, alumina)—each compatible with different processes such as FDM (Fused Deposition Modeling), SLS (Selective Laser Sintering), SLA (Stereolithography), or SLM (Selective Laser Melting).

Material development in 3D printing is a dynamic field. New materials with improved mechanical, thermal, or chemical properties are continuously being developed, targeting specific industries and expanding application areas. Challenges remain in process stability and standardization of material properties, especially for complex metal alloys.

Economics: A Matter of Scale and Complexity

Economic viability depends heavily on production volume, part complexity, and surface finish requirements. Additive manufacturing excels with prototypes and small series (typically up to a few thousand parts, depending on complexity) and is often the more cost-effective choice. For large series, however, traditional methods usually remain cheaper due to shorter cycle times per part (e.g., in injection molding) and lower unit costs from economies of scale.

Yet, especially for customized products, complex spare parts, on-demand production, or functionally integrated geometries, 3D printing can be more economical even at medium volumes. The ability to combine multiple functions into a single part (functional integration) or consolidate parts reduces assembly costs and material use, significantly lowering total costs.

Design Paradigm: Design for Additive Manufacturing (DfAM)

Additive manufacturing enables geometries that are impossible or very costly to produce with conventional methods. These include complex hollow structures, lattice geometries for weight reduction and material savings, or functional integration within a single part (e.g., cooling channels inside a mold, which would require multi-part design in subtractive processes).

This requires a shift in design thinking known as Design for Additive Manufacturing (DfAM). Designers and engineers must understand the constraints and possibilities of additive processes to fully leverage their benefits. Parts optimized for milling or casting rarely unlock the full potential of additive manufacturing.

Conclusion: Not Either-Or – But the Best of Both Worlds

Additive manufacturing does not necessarily replace traditional methods but complements them and opens up entirely new possibilities. In many industries, hybrid manufacturing—the strategic combination of subtractive and additive processes—is becoming a key strategy. For example, 3D-printed blanks can be precision-machined afterward to achieve tight tolerances.

The choice of the right manufacturing technology strongly depends on the specific part requirements, production volume, material properties, and costs. A deep understanding of both worlds is essential to achieve optimal results.

AM Worx supports you in finding the right technology for your application and in unlocking the full potential of additive and hybrid manufacturing strategies—competently, collaboratively, and solution-oriented.