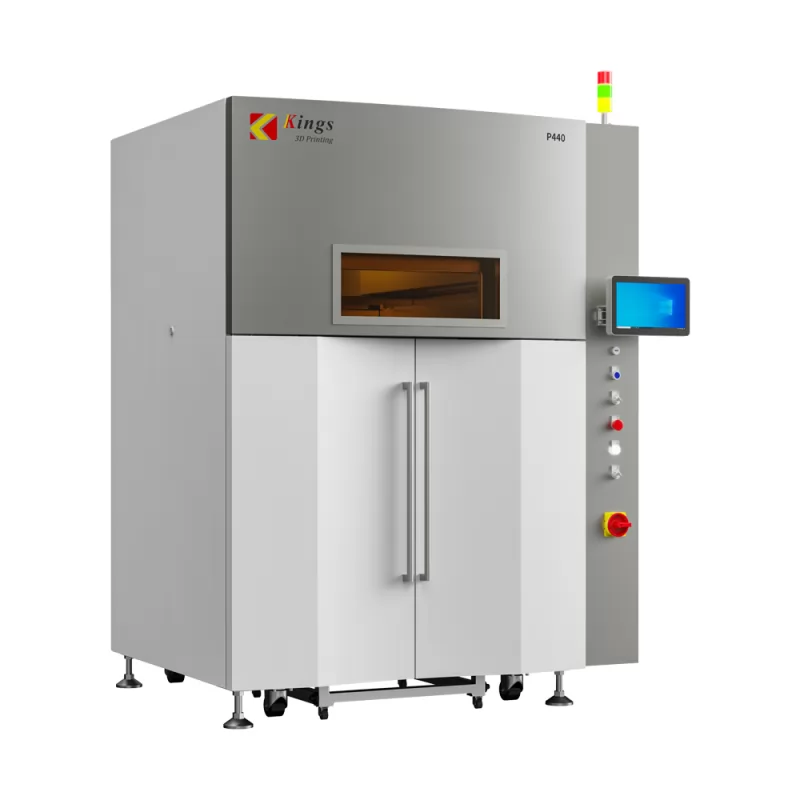

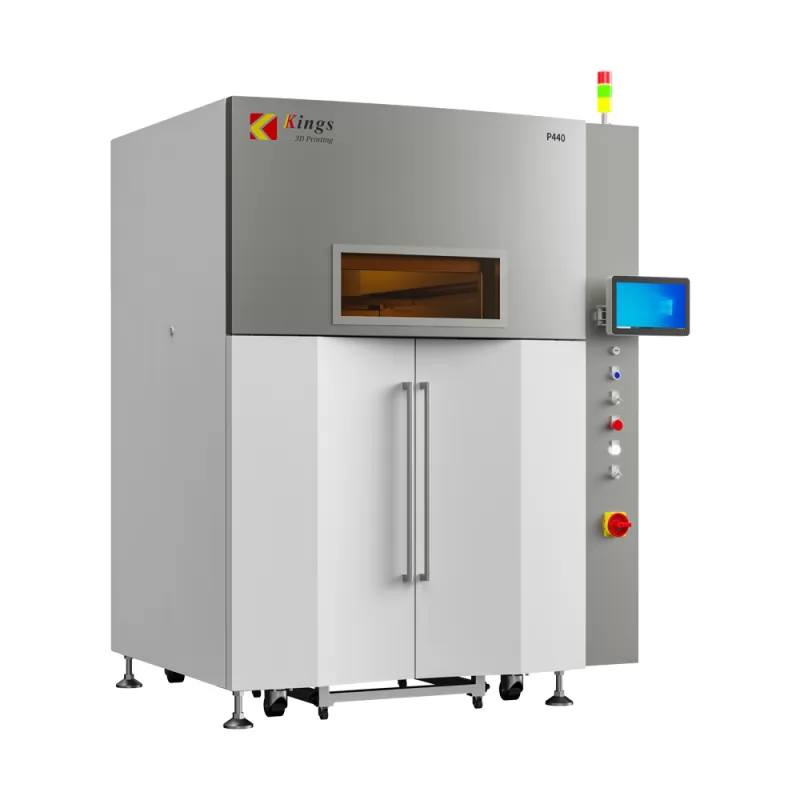

The Kings P440 SLS 3D printer is an industrial-grade solution for producing large and complex parts with high precision. With a generous build volume of 440 × 440 × 450 mm, it is ideal for prototyping, functional components, and small-batch production in industries such as automotive, medical technology, aerospace, and mechanical engineering.

Equipped with a powerful 60–100 W CO₂ laser and a three-axis dynamic scanning system, the P440 ensures consistent laser focus across the entire build area, resulting in highly detailed and accurate print results.

Its intelligent powder delivery system, featuring bidirectional recoating and dual blade spreading, enables uniform layer thickness and improves surface finish quality. In addition, the near-complete recyclability of unused powder supports cost-efficient and sustainable production.

With a maximum sintering temperature of 190 °C and eight-zone independent temperature control, the P440 maintains stable printing conditions essential for processing high-performance polymers.

The modular build cylinder allows for rapid job changes, minimizing downtime and maximizing productivity.

Overall, the Kings P440 provides a powerful and flexible SLS solution for industrial applications that demand high accuracy, material efficiency, and user-friendly operation.