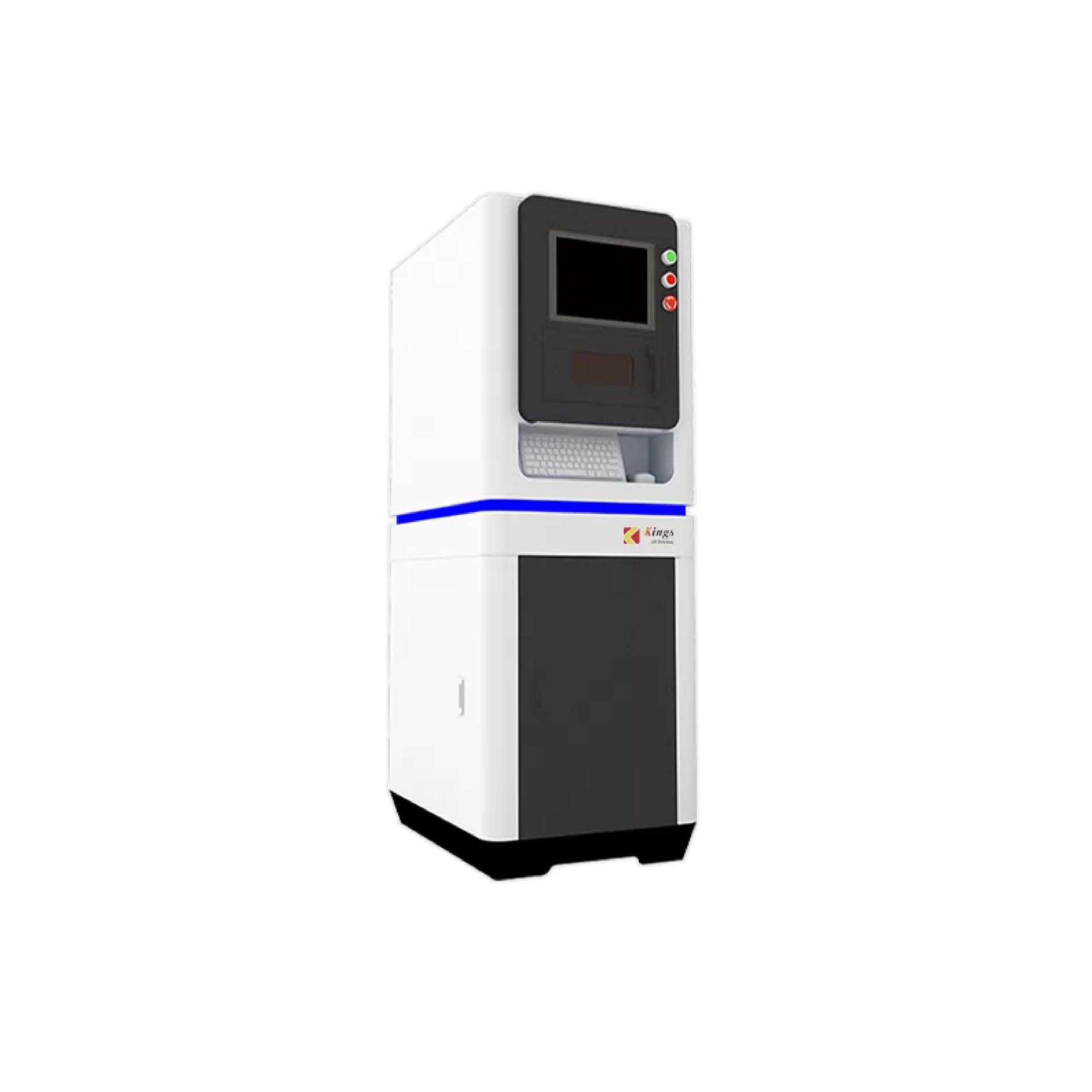

The Kings M50E is an industrial metal 3D printer based on Selective Laser Melting (SLM) technology, specifically designed for professional use in research, development, technical education, as well as for the production of small series and highly precise metal components. With a compact build volume of 70 mm diameter and 50 mm height, the Kings M50E is perfectly suited for manufacturing delicate metal parts with the highest demands on dimensional accuracy and detail resolution.

The integrated high-performance galvanometer optics ensure a printing accuracy of ±0.1 mm or ±0.1% for larger parts, while simultaneously guaranteeing a reliable and stable process. A significant advantage of this system is its gas-free operation, which considerably reduces both operating costs and maintenance effort. Additionally, a dual air circulation system protects the optical components from contamination and extends their service life.

The M50E is equipped with a powerful 200-watt fiber laser (1064 nm), a state-of-the-art scanner system, and intelligent software such as Voxeldance Additive or Magics. Control is handled via an industrial-grade Windows 10 system with a custom-developed user interface. Thanks to its compact external dimensions, low weight, and energy-efficient operation with just 1 kW power consumption, the Kings M50E is ideal for integration into existing production environments.

Typical applications include additive manufacturing in industry, dental technology, jewelry production, research and development laboratories, and technical educational institutions. With its high manufacturing quality, ease of use, and compact design, the Kings M50E offers an optimal entry into professional metal 3D printing or a valuable extension of existing manufacturing capacities.

SEO keywords: metal 3D printer, SLM 3D printing, industrial 3D printing, selective laser melting, metal additive manufacturing, dental 3D printing, jewelry 3D printing, metal 3D printing without shielding gas, Kings M50E.