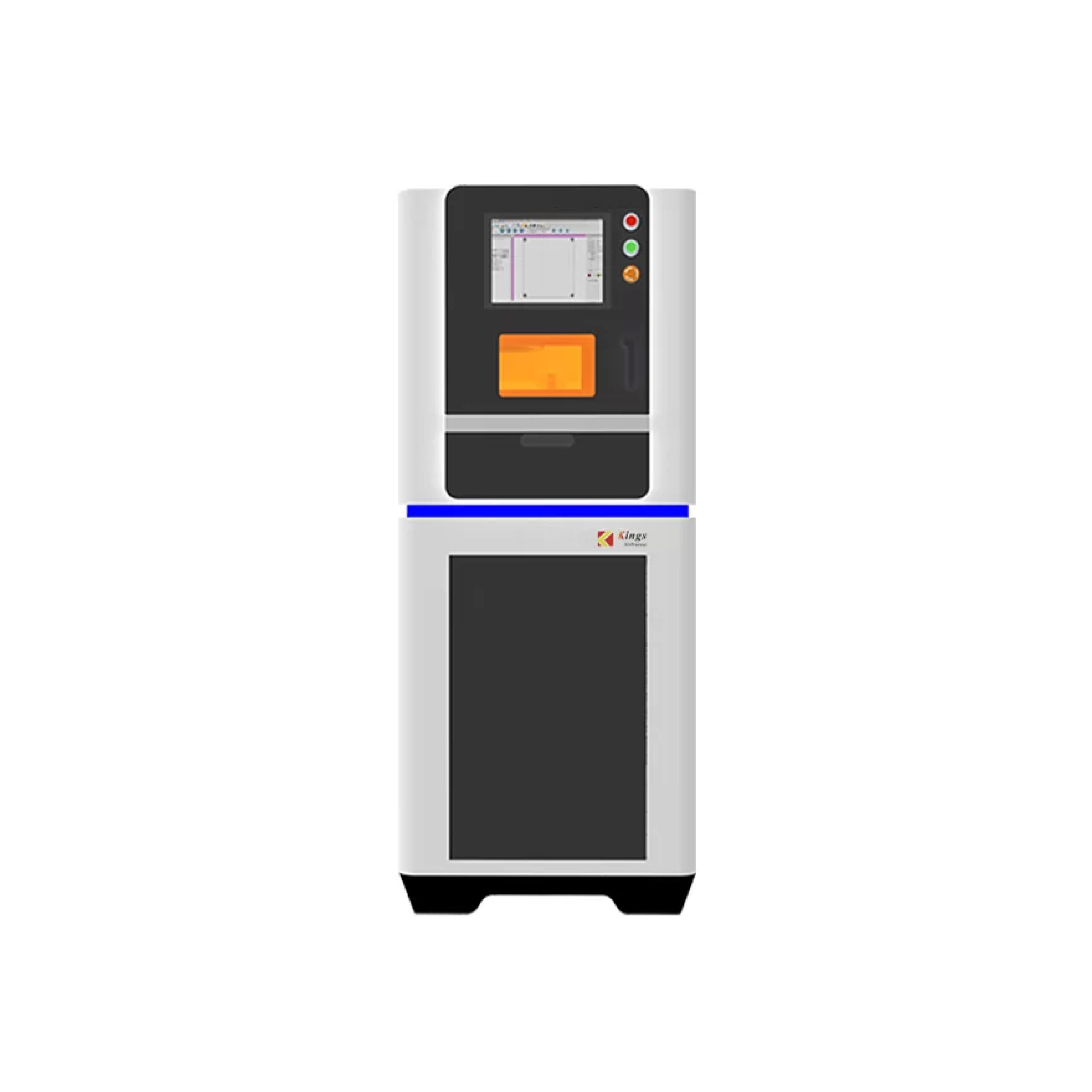

The Kings M100 series comprises high-precision SLM 3D printers designed for applications in dental technology, orthopedics, research, and jewelry manufacturing. Both models, Kings M100E and Kings M100H, offer a build volume of 100 × 100 × 100 mm and process high-quality metal powders such as titanium, cobalt-chrome, and stainless steel. Featuring a 20 μm laser spot and a 500-watt fiber laser, they deliver ultra-fine structures with high density and stability. The fully automated powder handling system with a retractable piston mechanism ensures rapid material changes without cross-contamination.

The difference lies in the target audience: the Kings M100E is aimed at industrial customers working with versatile materials, while the M100H is specially optimized for dental applications. Both devices are equipped with an efficient protective gas environment, dual air circulation system, and an intuitive control interface. Typical applications include dental technology, orthopedics, education, and precise small-batch production.

SEO Keywords: SLM 3D printer, dental 3D printing, metal 3D printer, Kings M100E, Kings M100H, selective laser melting, dental technology, metal powder 3D printing