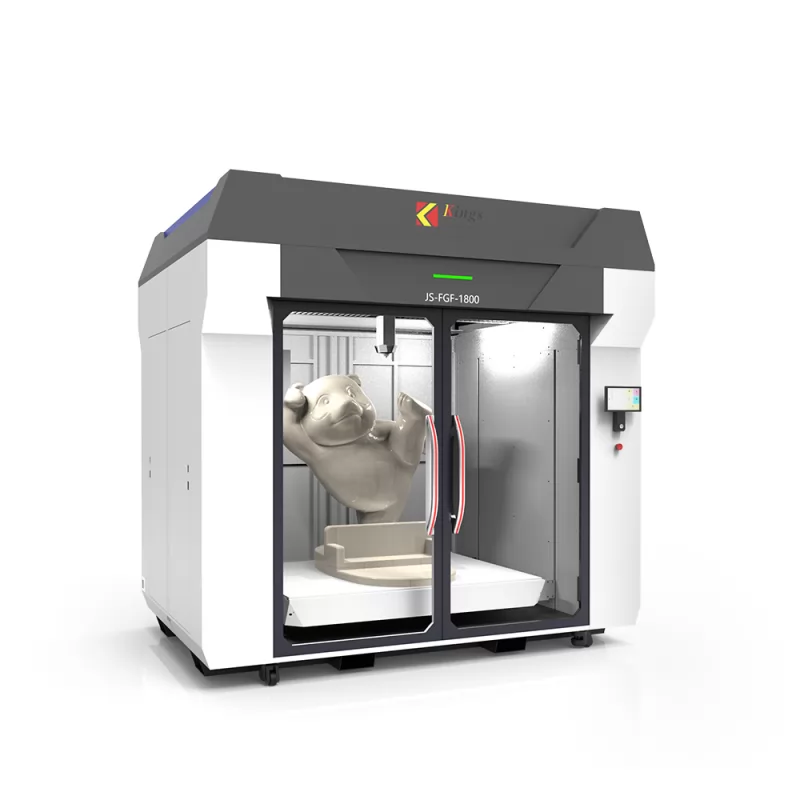

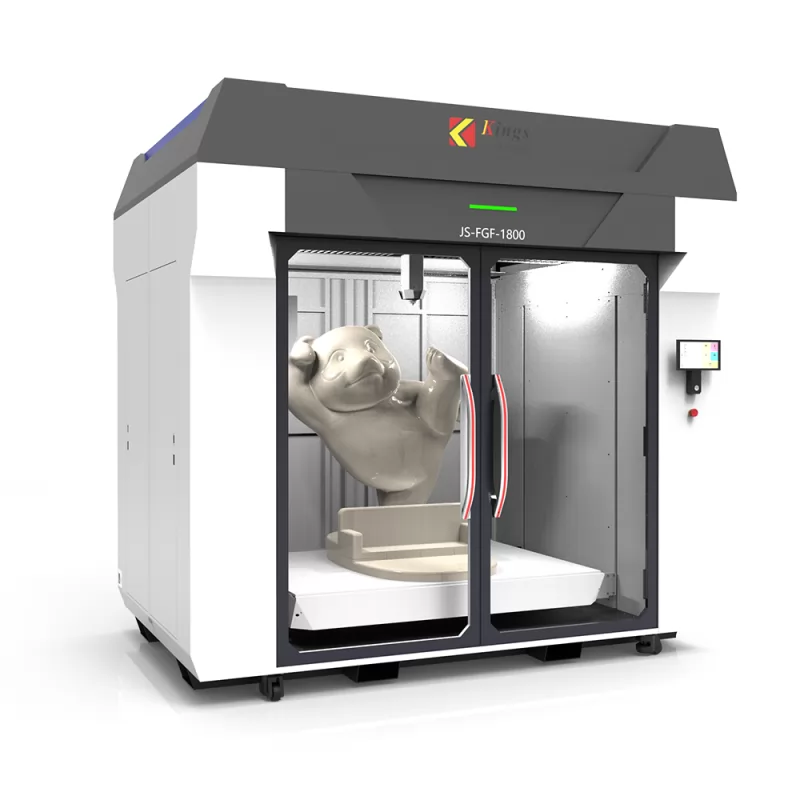

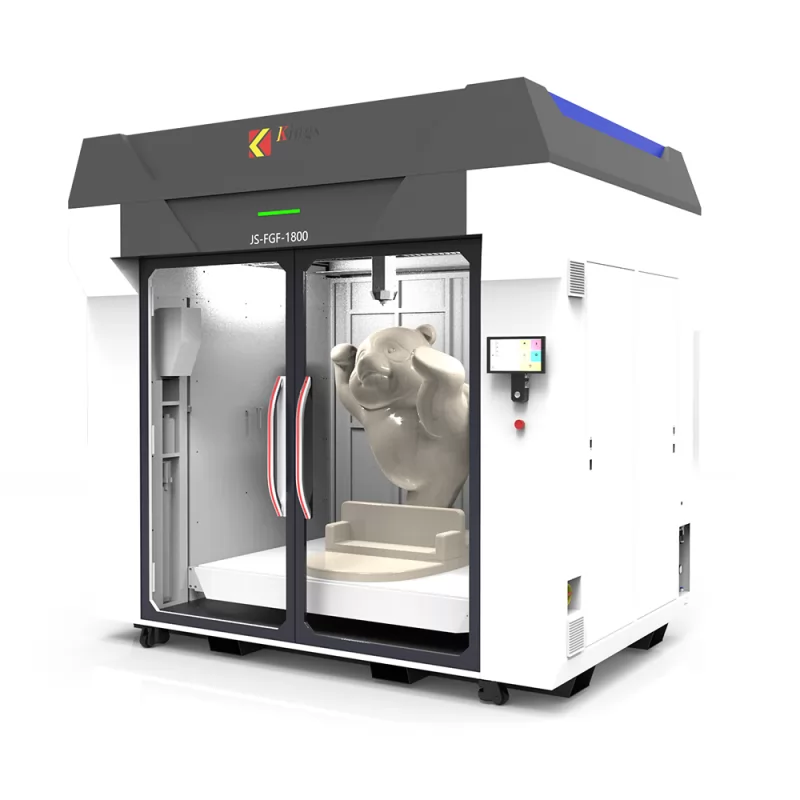

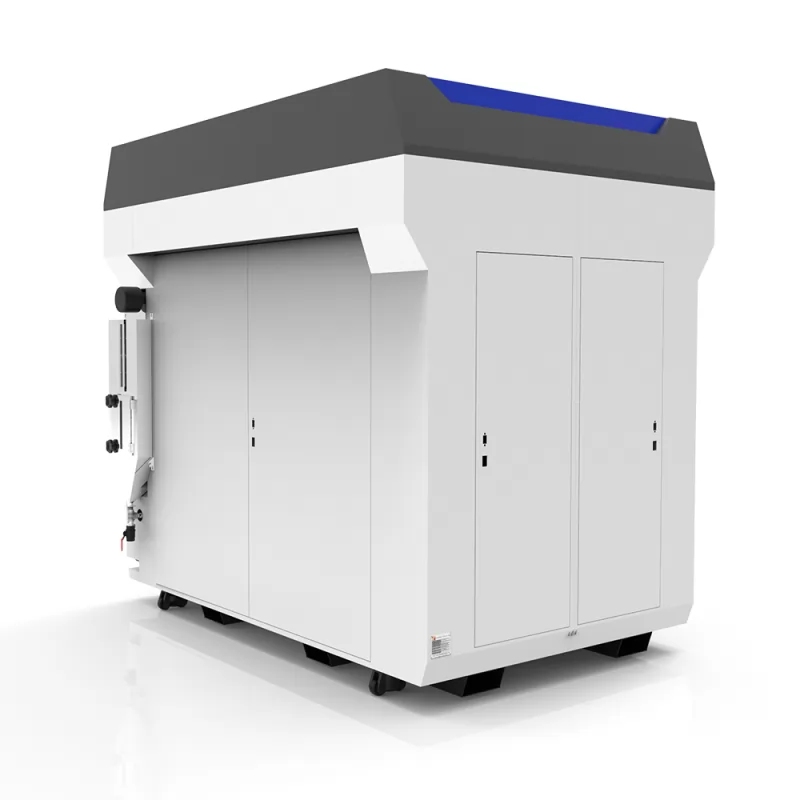

The Kings FGF 1800 (Fused Granular Fabrication) 3D printer redefines the limits of large-format manufacturing.

With its massive build volume of 1800 mm × 1000 mm × 800 mm, it enables the production of oversized parts in a single printing process—something that is hardly achievable with conventional additive manufacturing technologies at this scale. Like the FGF 800, the FGF 1800 is designed for the cost-efficient processing of plastic granulates, making it a groundbreaking solution for industries that require large, functional components at economical prices.

The ability to process standard thermoplastic granulates opens up a wide range of applications across sectors such as:

-

Boatbuilding (e.g., hull sections, large molds)

-

Wind energy (e.g., rotor blade molds, covers)

-

Construction (e.g., large-format formwork, architectural prototypes)

-

Automotive (e.g., body components, large tooling)

Compared to other large-format 3D printing technologies, the significantly lower material costs make the Kings FGF 1800 especially attractive to these industries.

Despite its impressive size, the Kings FGF 1800 delivers reliable and high-quality print results, enabling the creation of complex geometries. Its robust design ensures stability during the printing of such voluminous components. The flexibility to work with various thermoplastic granulates allows businesses to develop customized material solutions tailored to their specific applications.

The Kings FGF 1800 is a game-changer in large-scale additive manufacturing, offering new opportunities in design, prototyping, and end-use production for a broad range of industrial sectors.