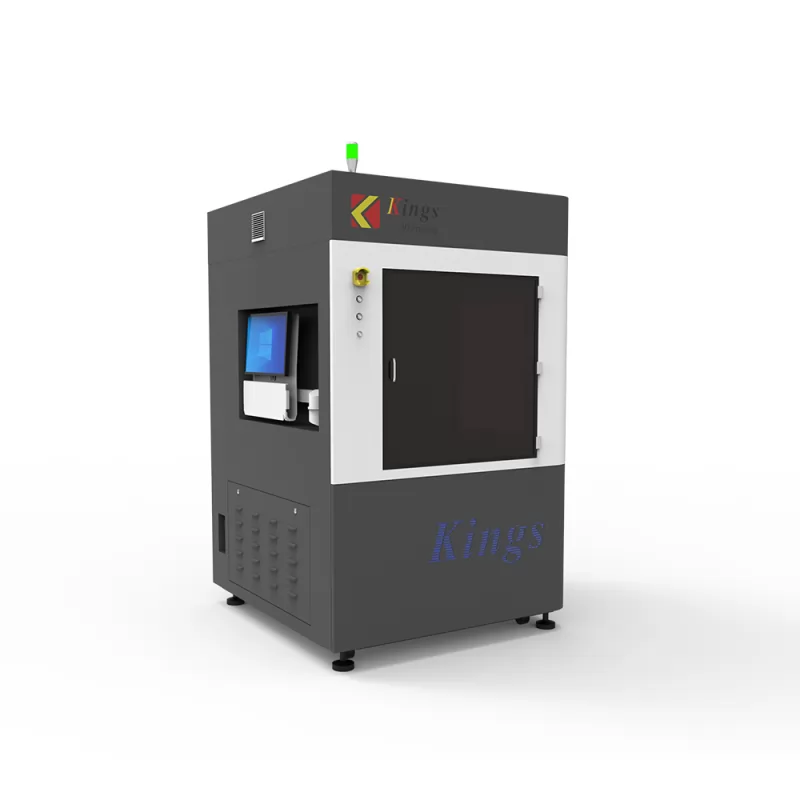

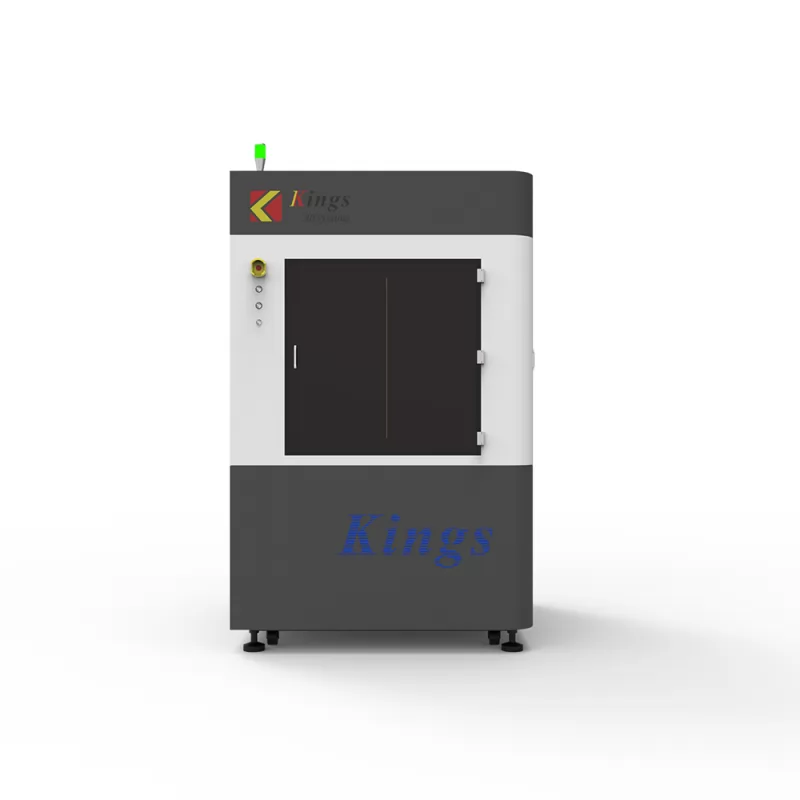

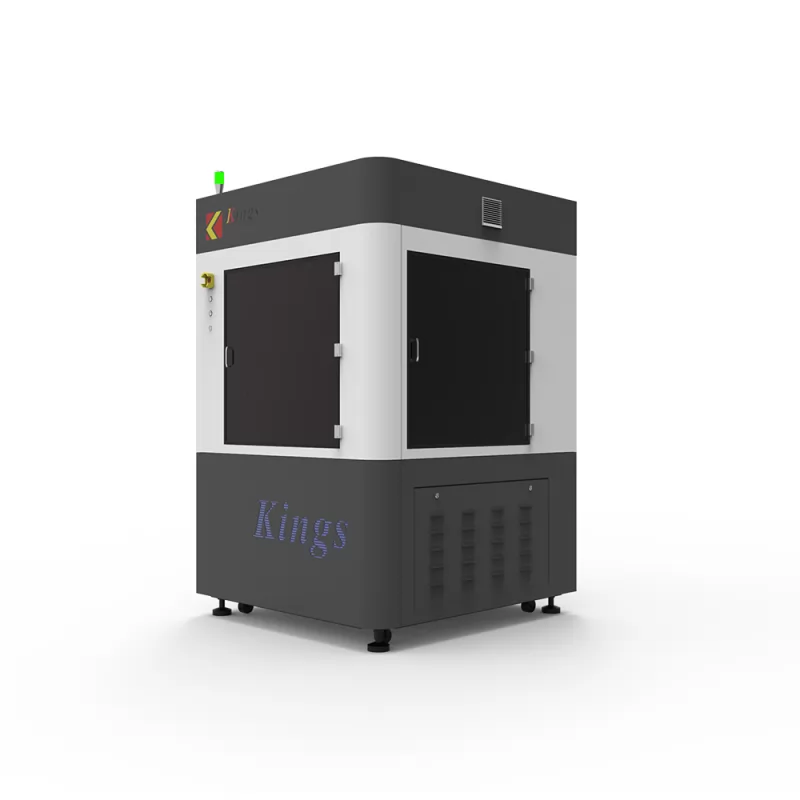

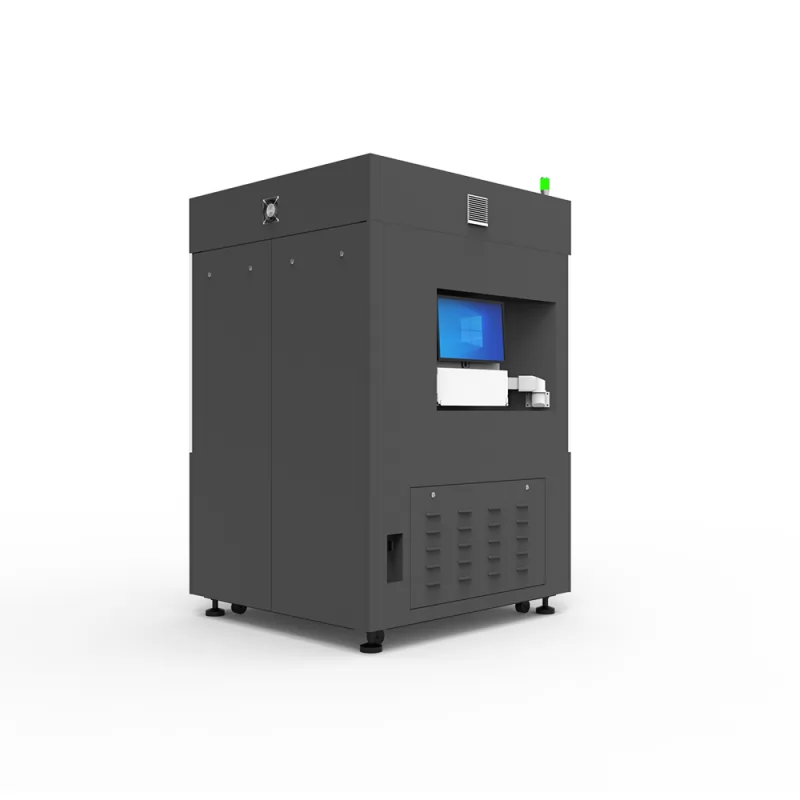

The Kings 850 SLA 3D printer presents itself as a high-quality and precise manufacturing solution for industrial applications that require a solid build volume of 850 x 850 x 500 mm. This system focuses on achieving the optimal balance between substantial production capacity and a compact footprint, making it an attractive choice for companies that prioritize efficiency and seamless integration into existing work environments. The Kings 850 SLA enables the production of medium-sized prototypes, functional components, and small series with the high level of detail and surface quality that stereolithography is known for.

Its application range is diverse and reflects its capability to deliver precise results in a practical size. In product development, it is ideal for quickly realizing design prototypes across various industries—from consumer goods and electronic housings to household appliance components. In mechanical engineering, it allows for the production of custom fixtures, tools, and replacement parts. The medical field also benefits from its ability to produce anatomical models for planning complex procedures or customized medical aids.

A key advantage of the Kings 850 SLA lies in its efficient material usage relative to build volume, making it an economical solution for repeated production cycles. Additionally, users benefit from mature SLA technology, which delivers excellent surface finishes and fine details—a decisive factor in applications with high visual or functional demands. The Kings 850 SLA thus bridges the gap between small desktop devices and large-scale production systems, offering a powerful and cost-effective solution for a wide range of industrial 3D printing applications.