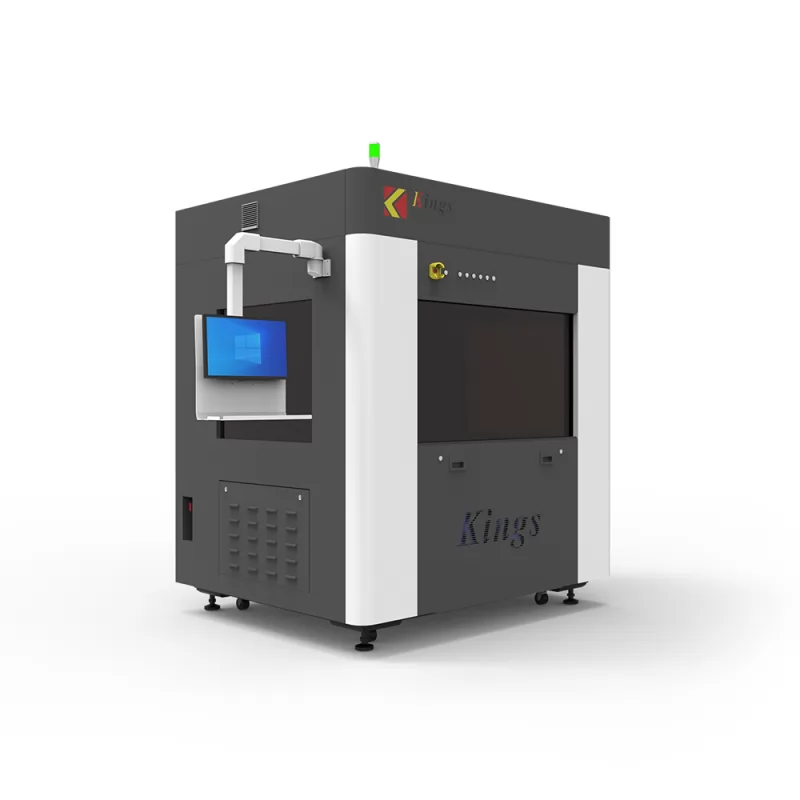

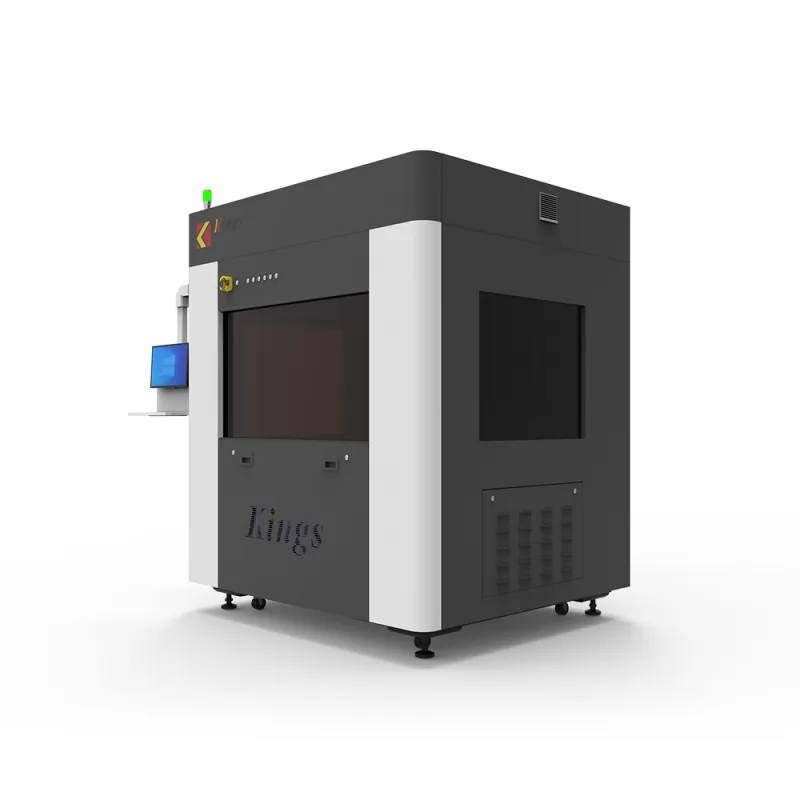

The Kings 1200 SLA 3D printer presents itself as a powerful and versatile solution for industrial applications requiring a large build volume of 1200 x 1200 x 650 mm. This impressive dimension enables the production of substantial components in a single piece, significantly enhancing design freedom and efficiency in production processes. The ability to realize voluminous prototypes and end-use parts without the need for assembly saves time and reduces potential sources of error.

The application possibilities of the Kings 1200 SLA are diverse and span various industries. In the automotive sector, its generous build space allows for the production of larger interior or exterior components such as dashboard segments or aerodynamic elements in one uninterrupted process. In the aerospace industry, it supports the creation of large prototypes and potentially even end-use parts. Architects benefit from its capacity to produce large-scale architectural models that clearly illustrate complex structures and spatial relationships.

Additionally, the Kings 1200 SLA is used in boat building for the production of hull segments or design studies, in the manufacture of large consumer goods such as housings for household appliances or furniture components, and in medical technology for developing large-scale anatomical models or customized prosthetics. The arts and design sectors also gain new creative possibilities, as the large build volume allows for the realization of ambitious projects and installations.

With its ability to produce precise, highly detailed objects in combination with the efficiency of a large build volume, the Kings 1200 SLA positions itself as a forward-looking solution for demanding 3D printing applications.