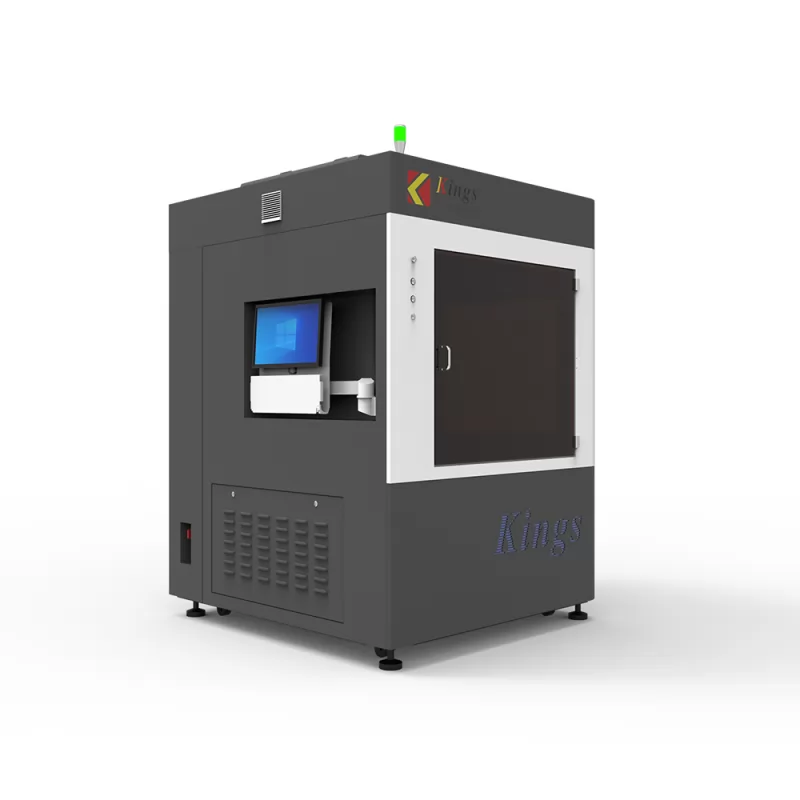

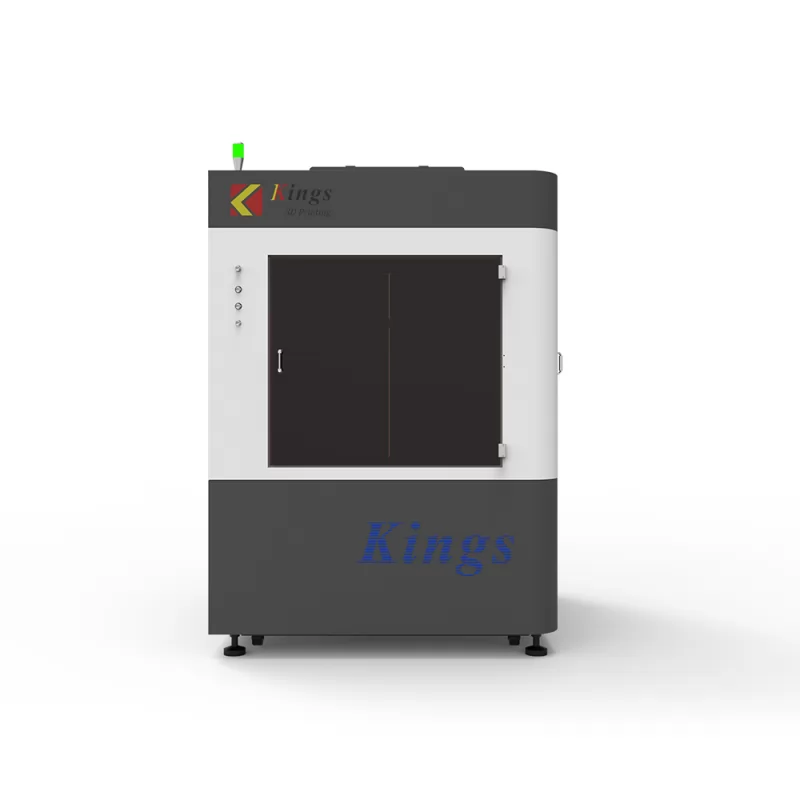

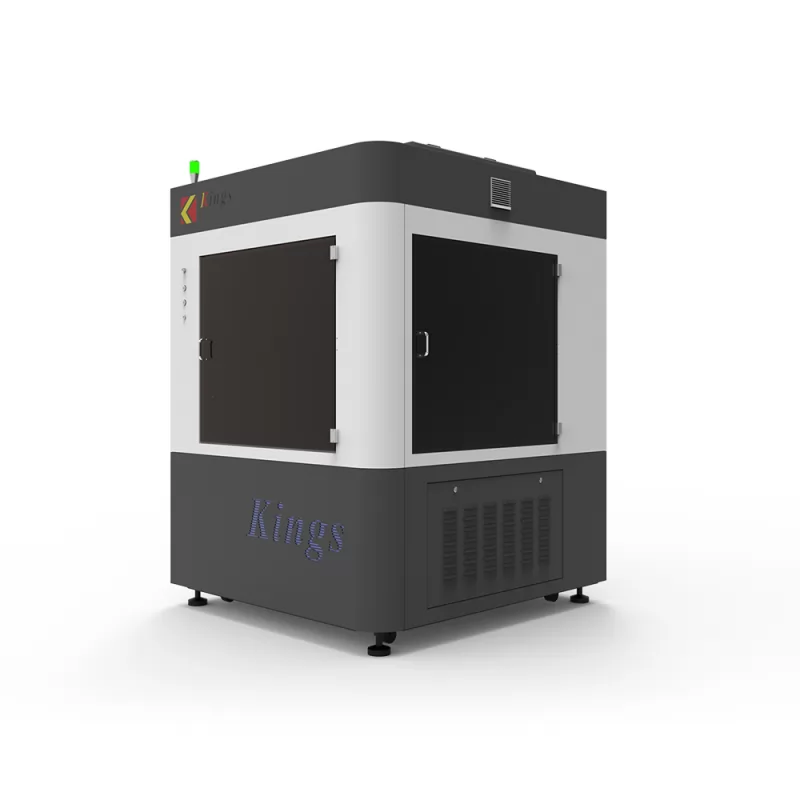

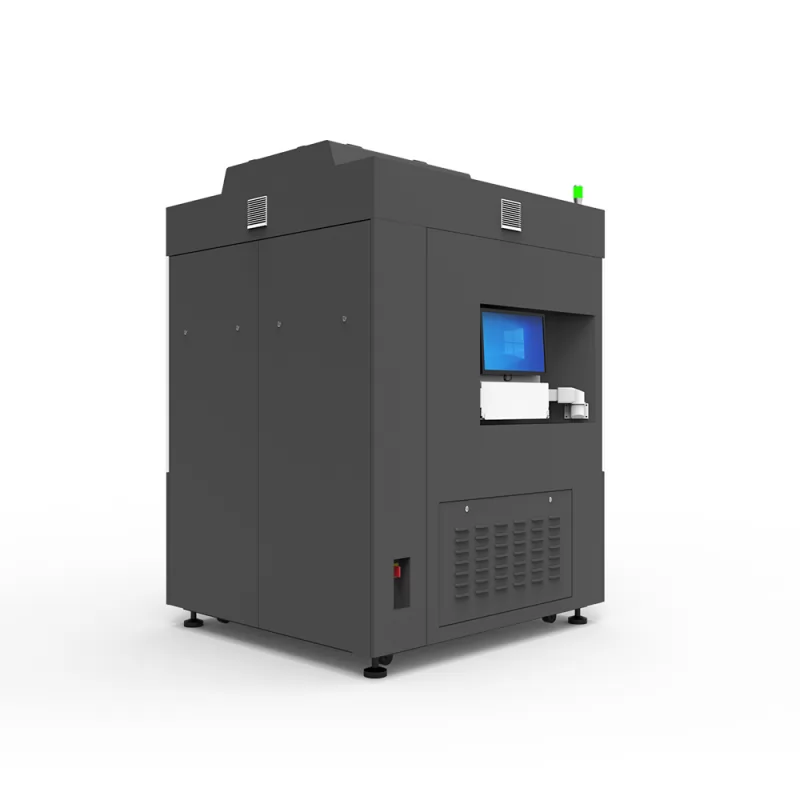

The Kings 1000 SLA 3D printer positions itself as a highly versatile and powerful solution in the field of industrial stereolithography. Its generous build volume of 1000 x 1000 x 600 mm offers an ideal balance between the ability to manufacture medium to large components in a single piece and an optimized footprint compared to even larger systems. This dimensioning makes it an attractive option for companies that value both the production of substantial prototypes and small series as well as the efficient use of their production environment.

The application areas of the Kings 1000 SLA are broad and demonstrate its flexibility. In the automotive industry, it enables the production of interior components such as center consoles or door panels in original size, as well as larger tools and fixtures for the production line. In the consumer goods industry, it offers the ability to efficiently realize housings for larger devices, design prototypes for furniture or sporting goods, and customized products. In the education sector and research institutions, its build size is ideal for creating complex models and demonstration pieces in the fields of engineering, design, and medicine.

Beyond that, the Kings 1000 SLA is used in specialized fields such as the creation of master patterns for investment casting, the production of gauges and inspection fixtures, as well as in creative industries for manufacturing large-format art objects and design installations. Its combination of significant build volume and the renowned precision of SLA technology makes it a valuable tool for companies that require functional prototypes, high-quality small series, and customized end-use parts — all in a practical size and with excellent surface quality. The Kings 1000 SLA thus bridges the gap between pure large-format production and the need for an efficient and versatile 3D printing solution.