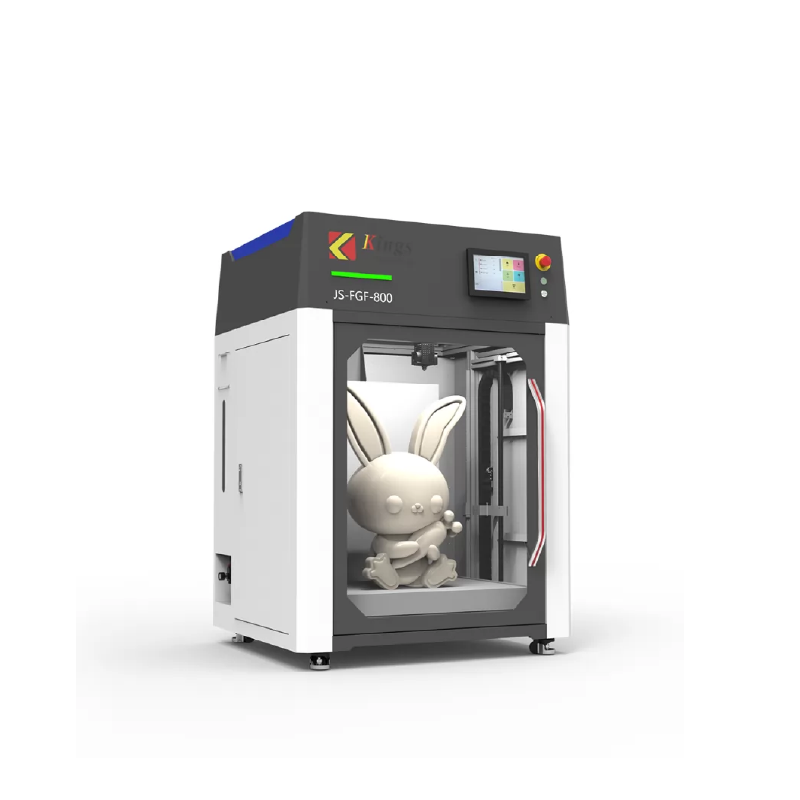

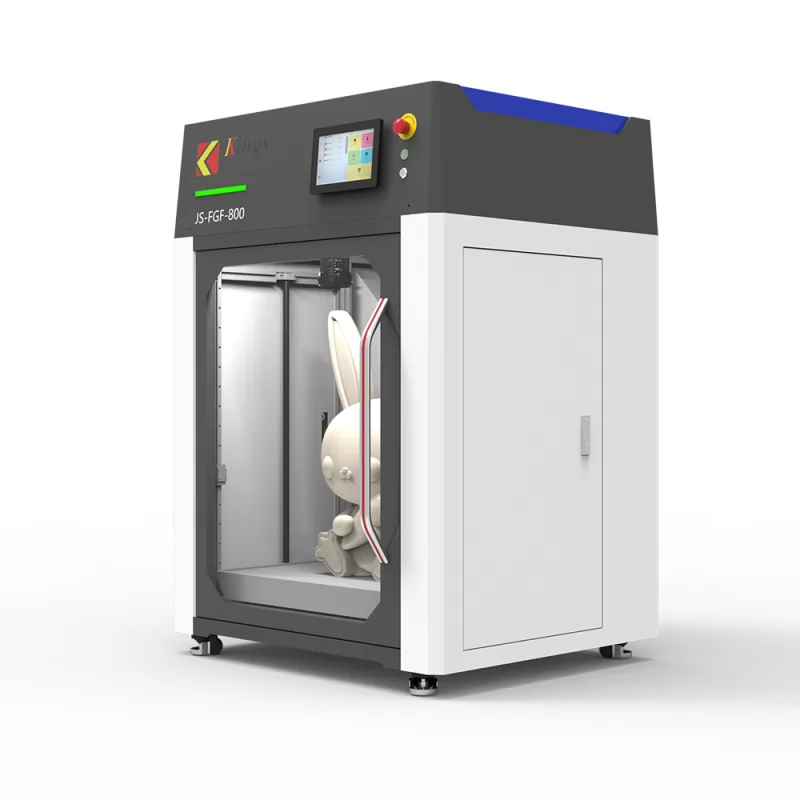

The Kings FGF 800 (Fused Granular Fabrication) 3D printer is revolutionizing large-format manufacturing with its focus on cost efficiency and the processing of a wide range of granulate materials. Featuring a generous build volume of 800 x 600 x 800 mm, it enables the production of functional prototypes, tools, jigs, and even end-use parts of impressive size at significantly lower material costs compared to conventional powder bed or resin-based processes.

The FGF technology allows the use of standard plastic granulates, which are generally much more affordable than specialized 3D printing filaments or powders. This makes the KINGS FGF 800 an attractive option for applications where volume and functionality are paramount and material costs play a decisive role. The printer can process various thermoplastics, broadening its applications across industries such as automotive (e.g., large prototypes, molds), furniture design (e.g., customized design elements), architecture (e.g., large-scale models), and the production of tools and fixtures.

Despite its cost-efficiency focus, the KINGS FGF 800 delivers solid print quality and repeatability. Its robust construction ensures stability throughout the printing process of large parts. The ability to customize material blends and properties through the use of granulates further opens new possibilities in material development and adaptation for specific applications. The KINGS FGF 800 is thus a forward-looking solution for companies aiming to economically and flexibly manufacture large-format, functional parts.