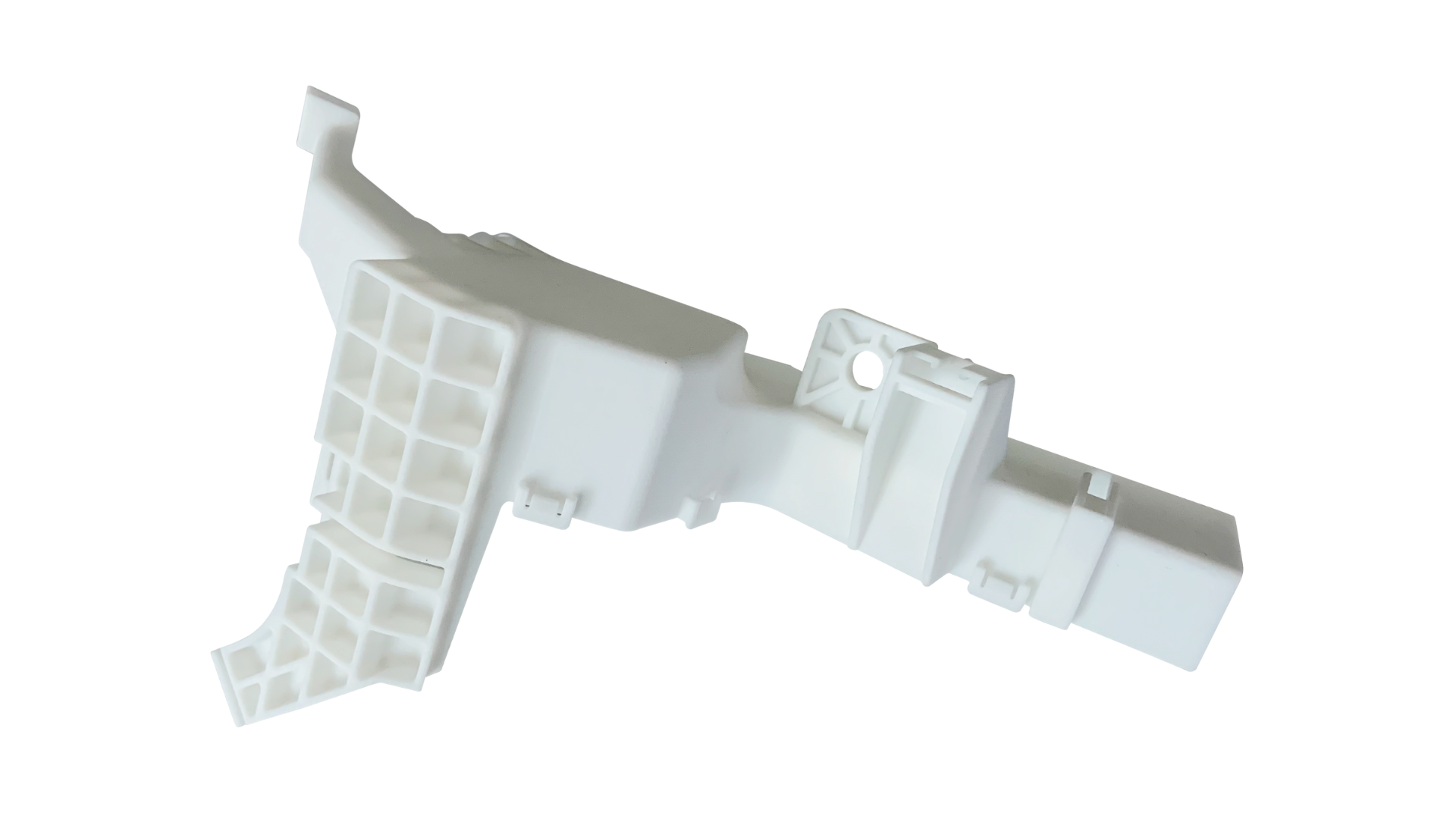

If prototypes need to be more than just good-looking – if they need to function – then SLS (Selective Laser Sintering) is the ideal choice. This industrial 3D printing process uses laser technology to shape powdered plastics, without support structures, resulting in impressive durability and dimensional accuracy.

SLS printing combines the best of both worlds: technical performance and design freedom. Thanks to its powder-based build process, complex geometries, interlocking components, and functional prototypes can be manufactured without compromising stability or accuracy.

You’ll receive parts that not only look good but also prove themselves in practical applications, such as in mechanical engineering, the automotive sector, or medical technology.