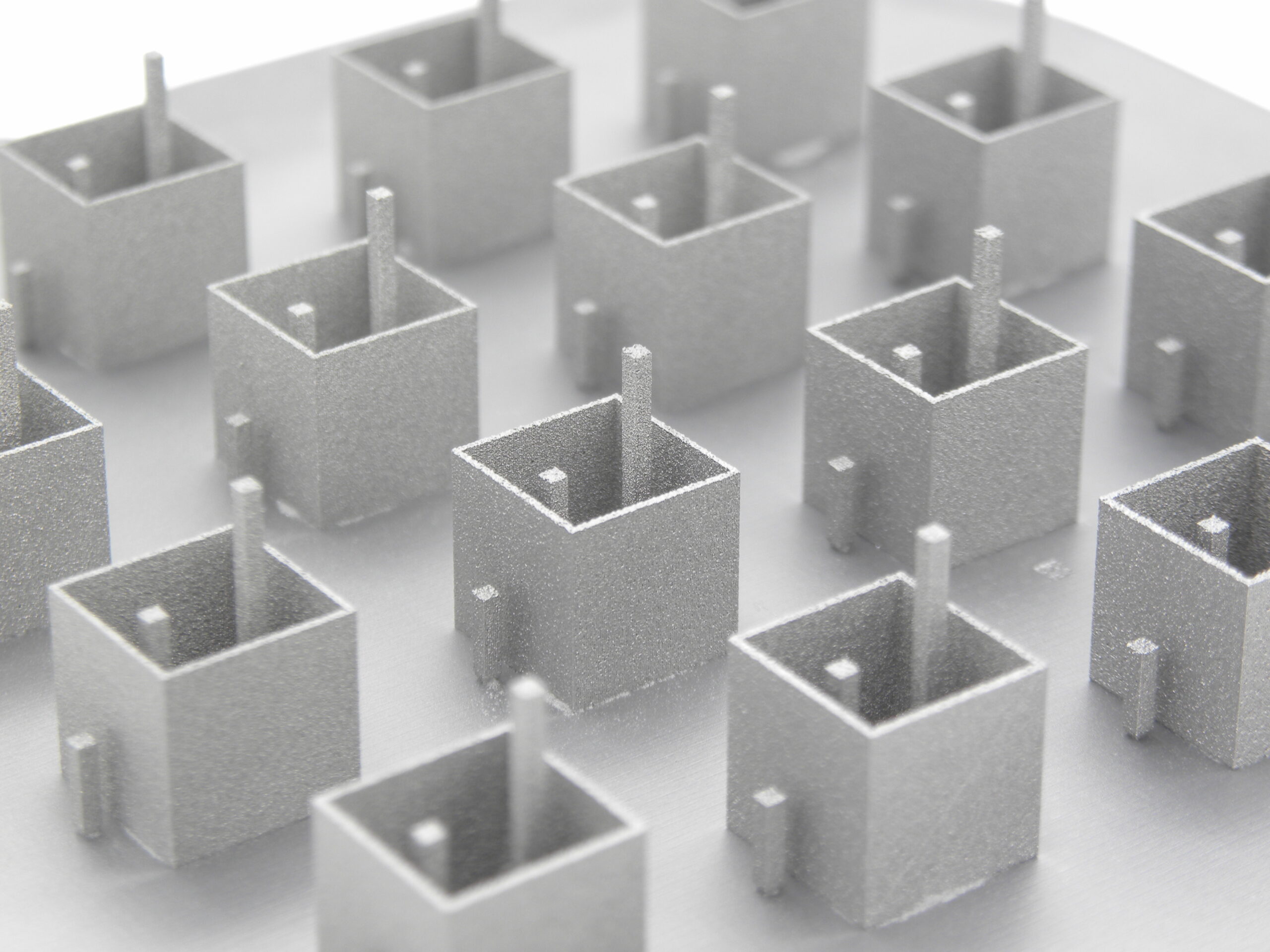

SLM (Selective Laser Melting) shapes metal, layer by layer, directly from a digital model. This high-end 3D printing process produces high-strength, fully functional metal parts that often surpass traditional manufacturing methods in precision and complexity.

Whether it’s a one-off production, a complex lightweight component, or a functionally integrated part, SLM offers state-of-the-art manufacturing without detours.

SLM uses metal powder—such as titanium, aluminum, or stainless steel—which is fully melted by a powerful laser. The result: dense, durable metal components that can be easily machined, welded, or used directly.

You benefit from maximum design freedom, minimal material usage, and highly precise results—ideal for industries where every micrometer counts.