What Makes SLA So Special?

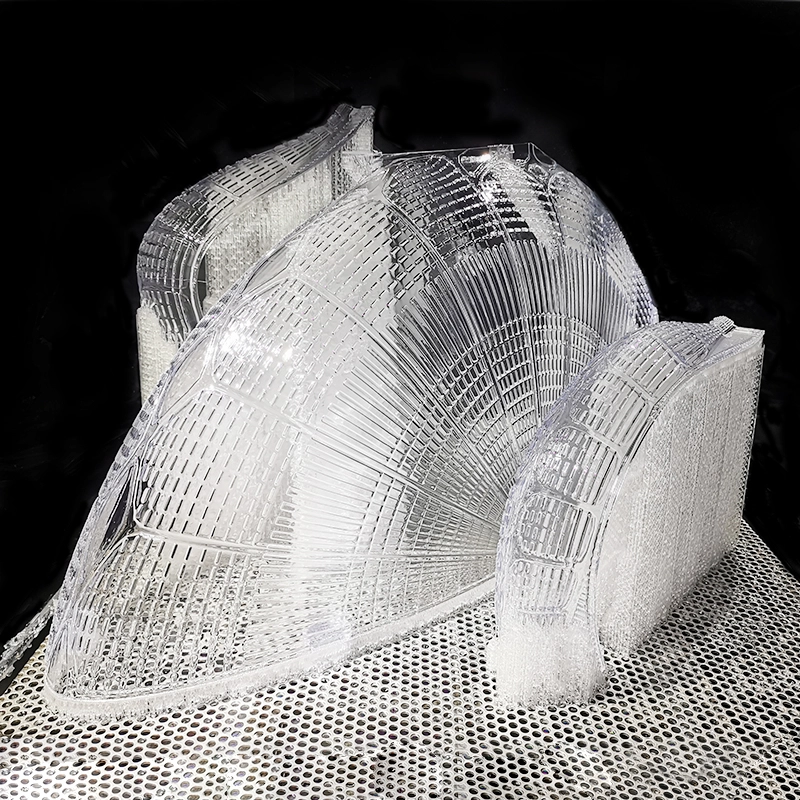

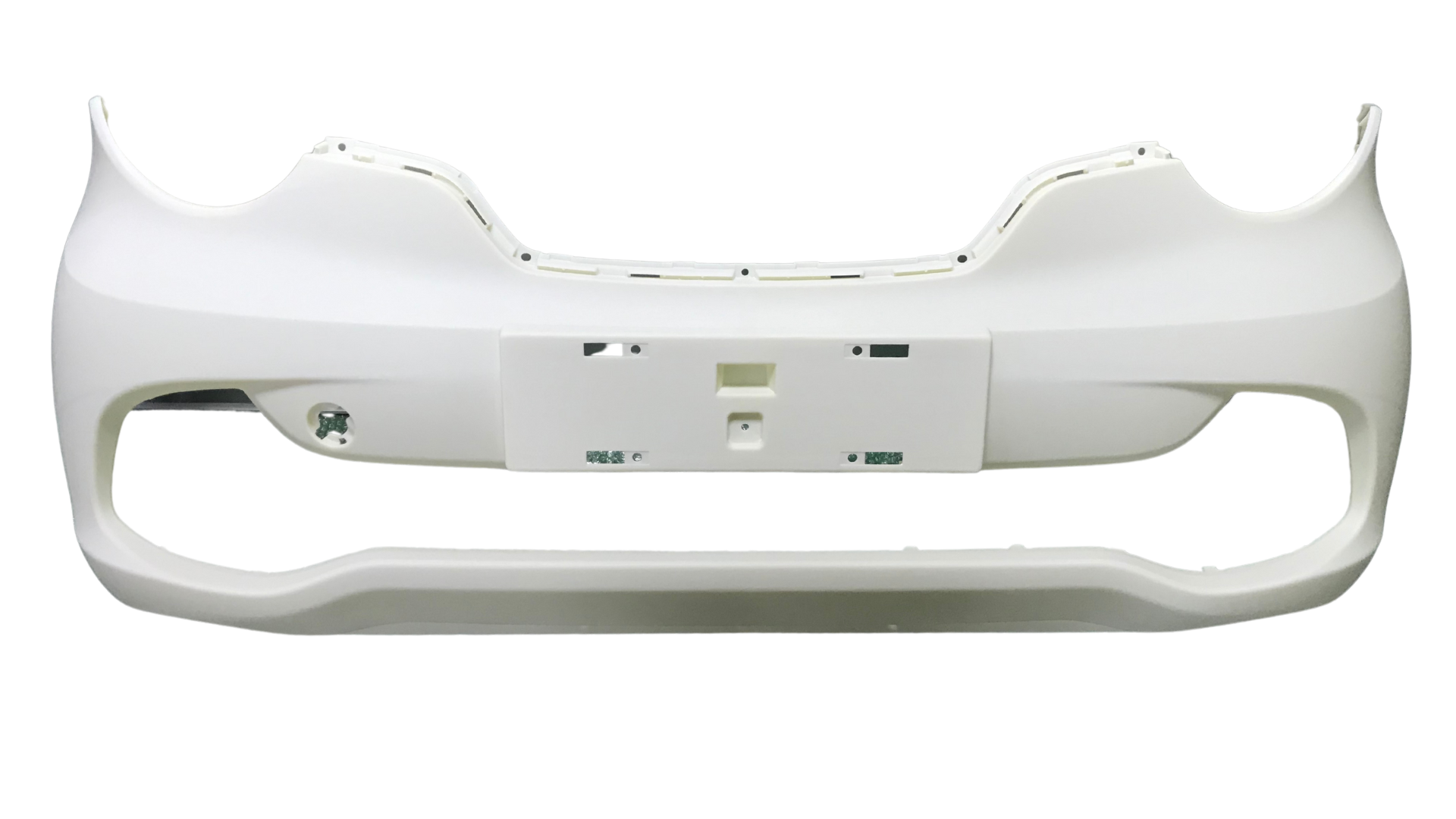

When the highest precision and finest details are required, SLA (Stereolithography) is the go-to technology. This high-resolution 3D printing process uses liquid resin that is cured layer by layer with UV light to create flawlessly detailed parts — delivering impressive depth and smooth, nearly perfect surfaces.

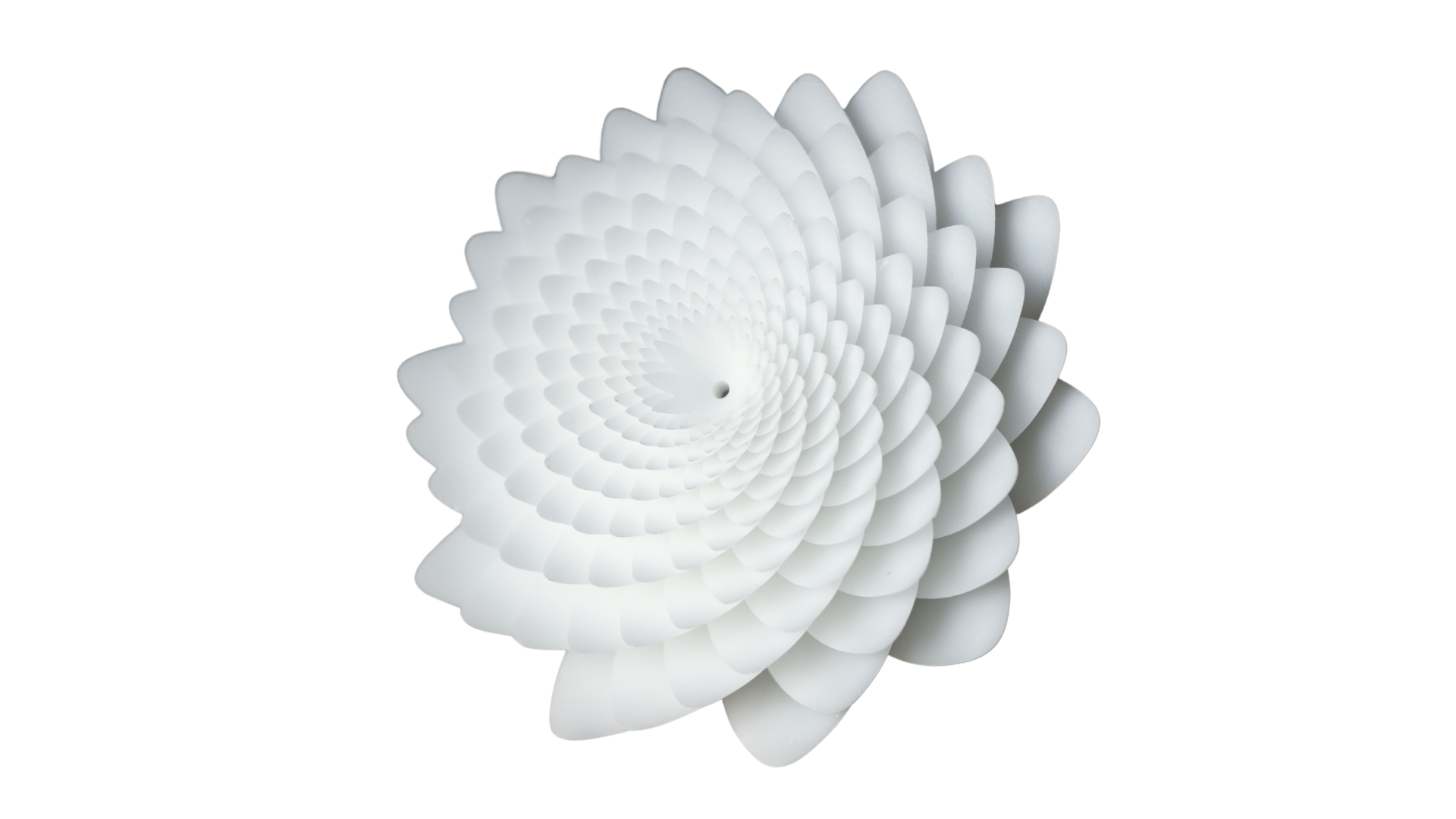

Compared to other 3D printing methods, SLA offers unmatched accuracy. Even the most delicate shapes, intricate engravings, and thin walls are reproduced with razor-sharp clarity. Visible layer lines are minimal, resulting in parts that often look like they were cast in one piece.

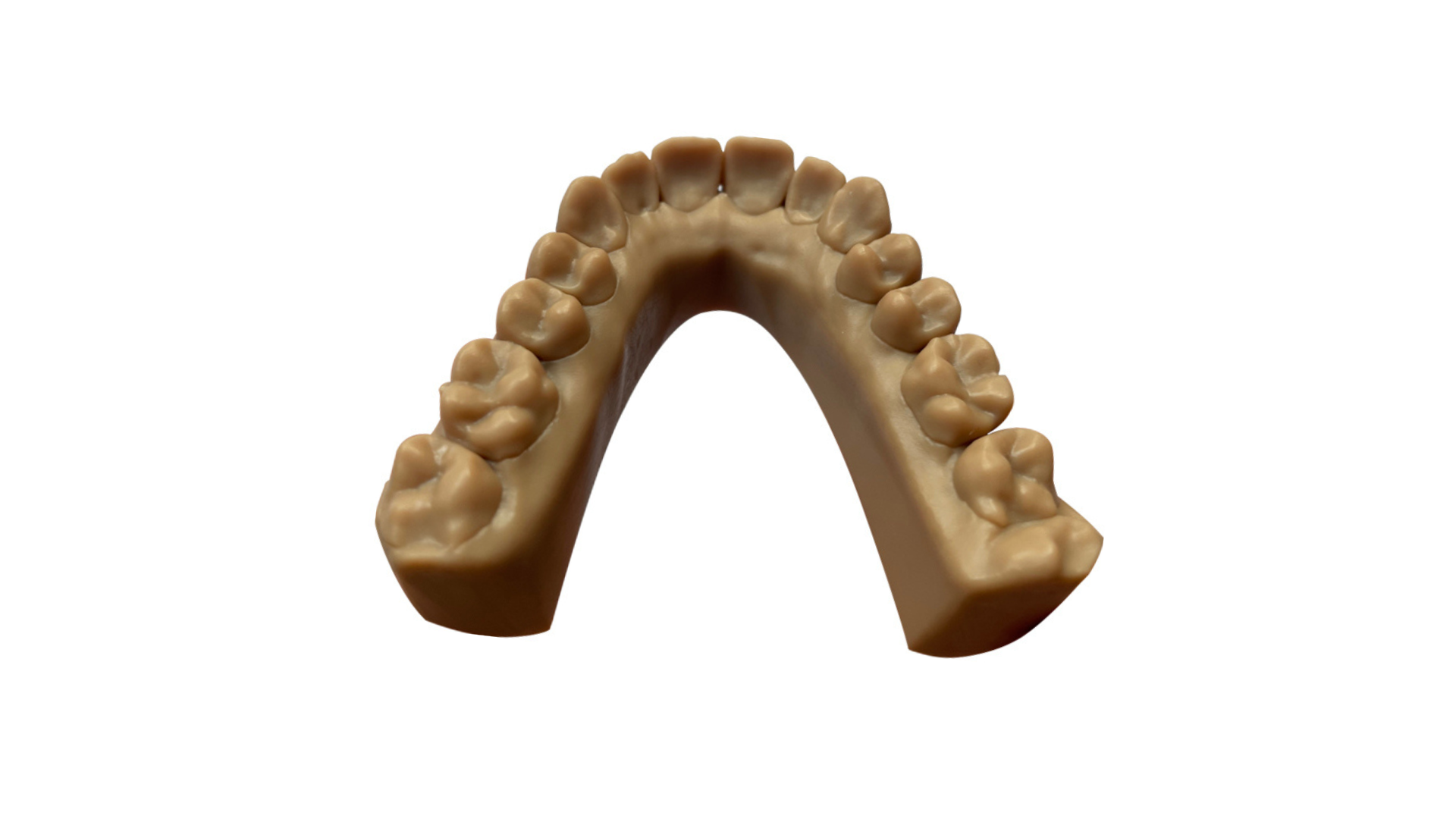

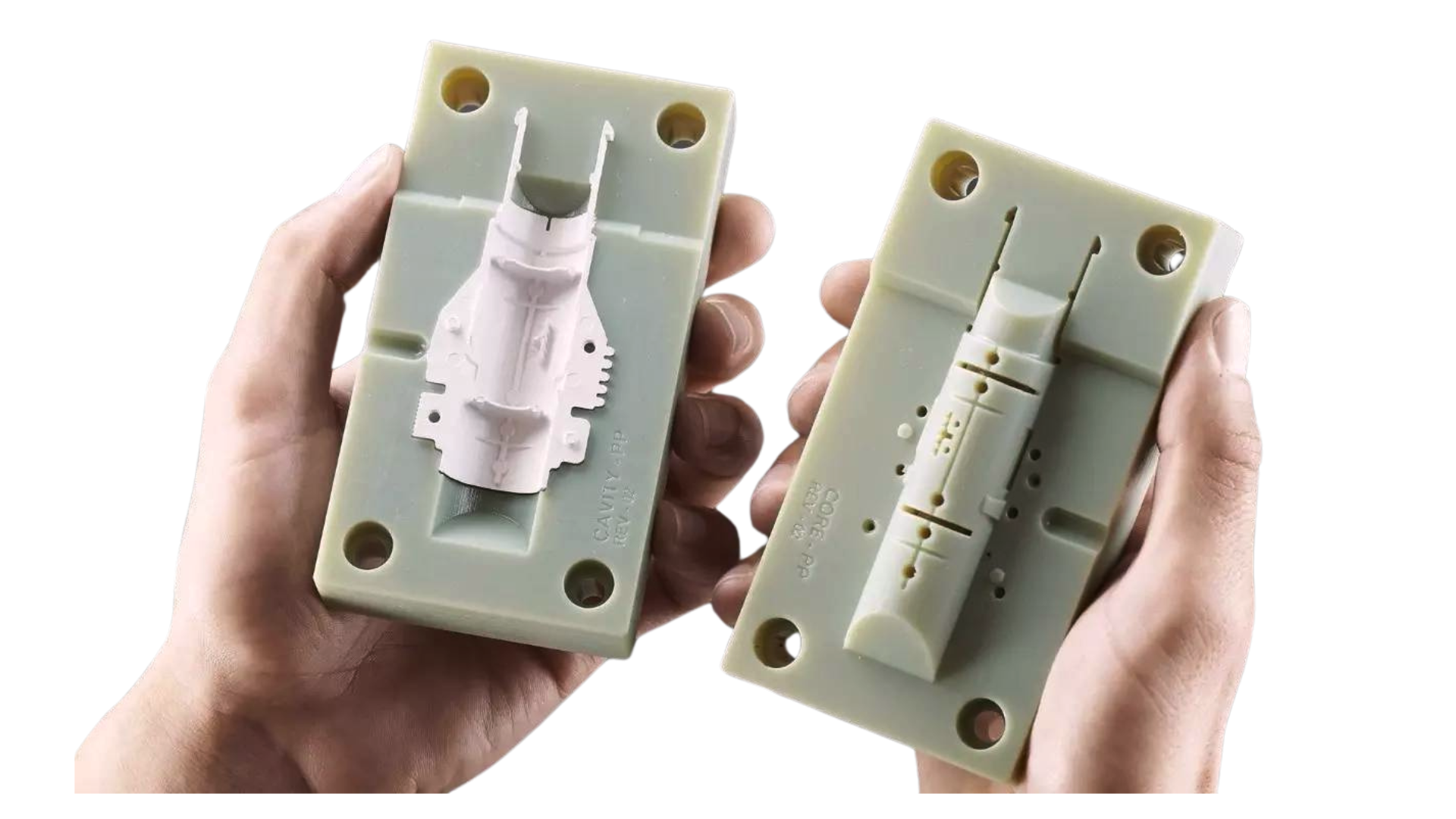

From initial product concepts and medical models to premium design objects, SLA enables fast, precise, and high-quality realization of your projects.