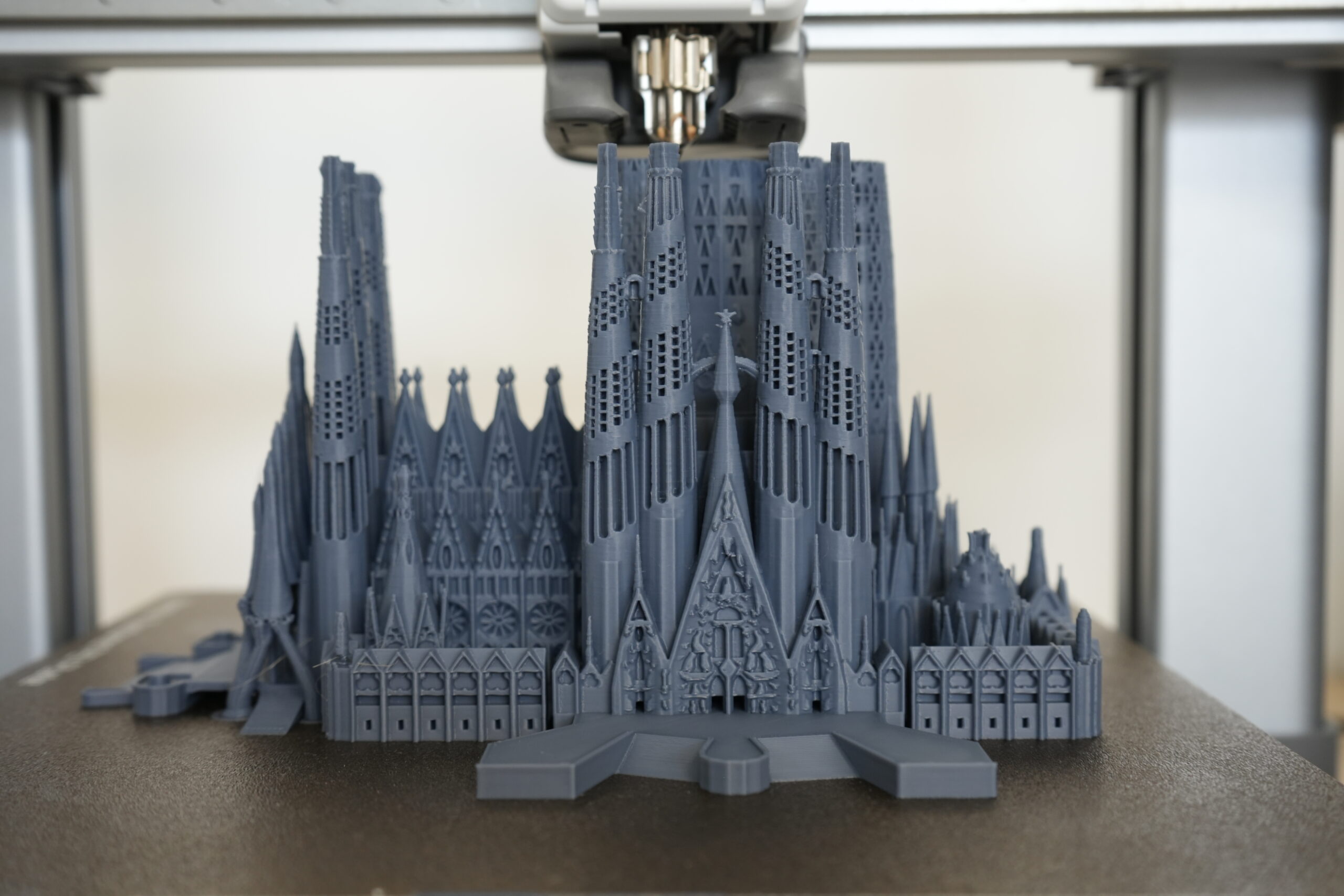

3D printing technology is no longer just a method for rapid prototyping. It has established itself across numerous industries as an indispensable tool that enables innovative solutions and revolutionizes manufacturing. Whether in industrial design, medical technology, automotive engineering, or architecture — 3D printing opens up entirely new possibilities in production, development, and manufacturing.

Thanks to the flexibility and precision of 3D printing, nearly every industry can benefit from this advanced technology. With various 3D printing processes, we offer tailored solutions for almost every application.