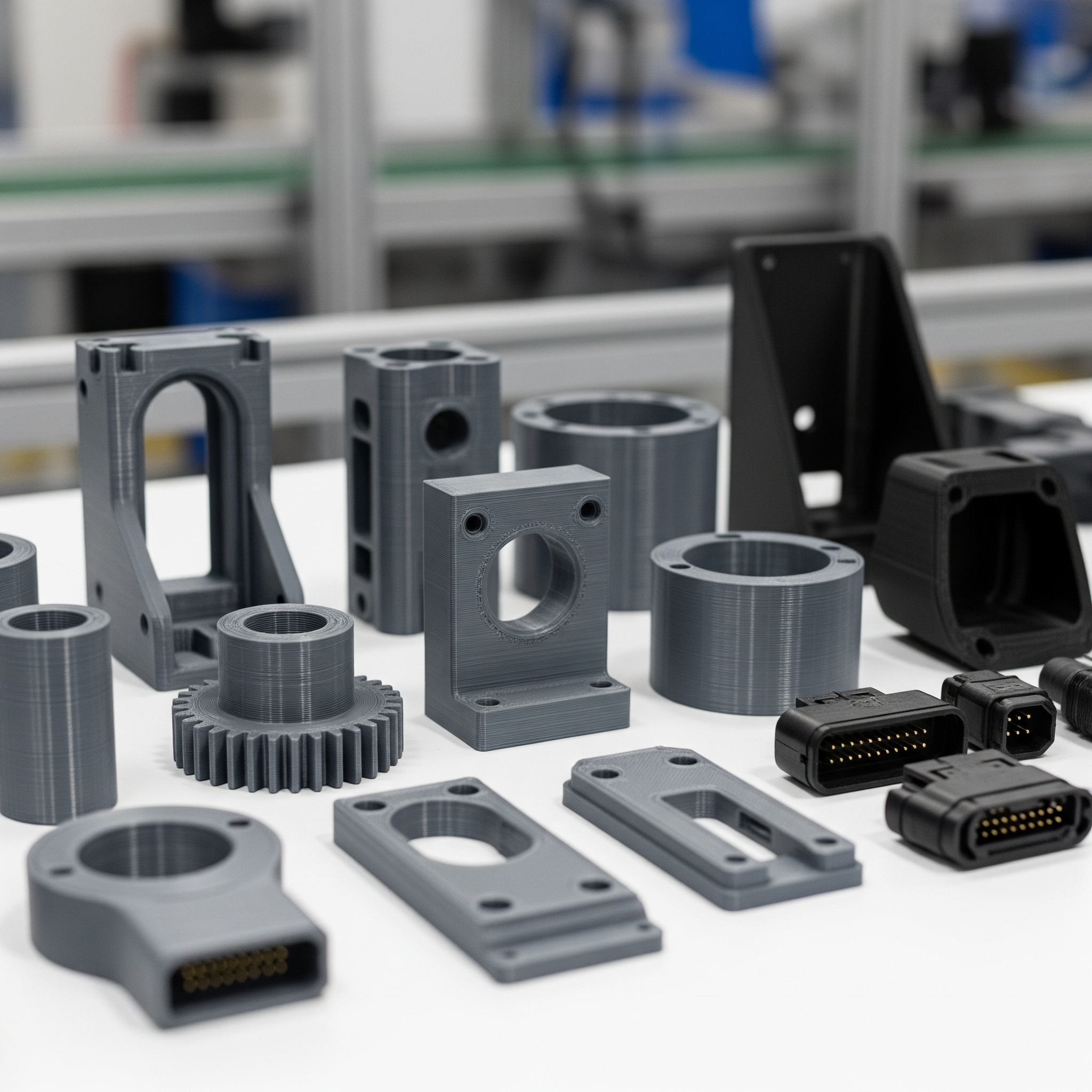

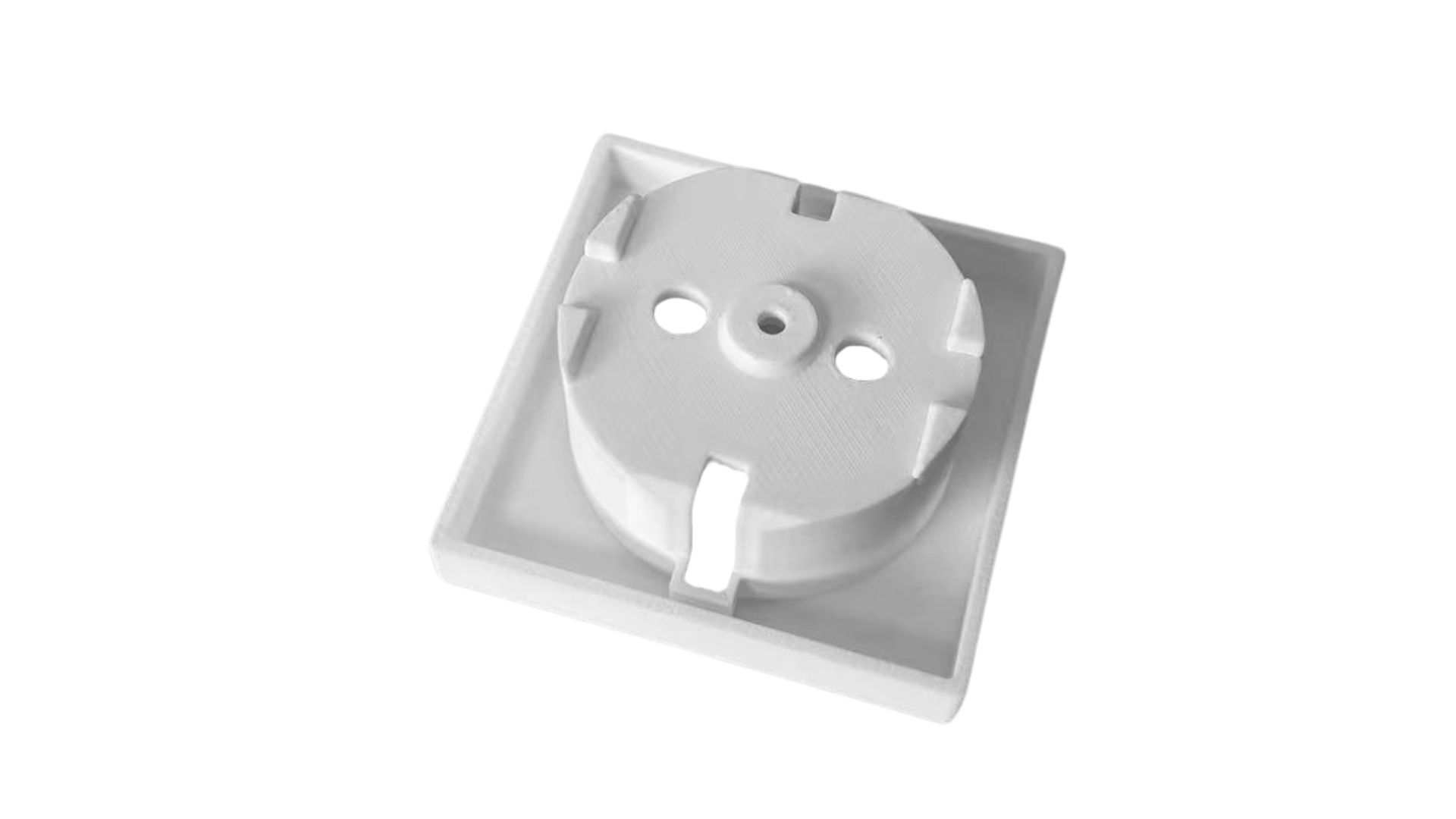

FDM (Fused Deposition Modeling) is the most well-known and widely used 3D printing technology — and for good reason. It offers the perfect balance of cost efficiency, durability, and material variety. Whether it’s a functional prototype, spare part, or assembly aid, FDM delivers fast, reliable results that stand up to everyday use.

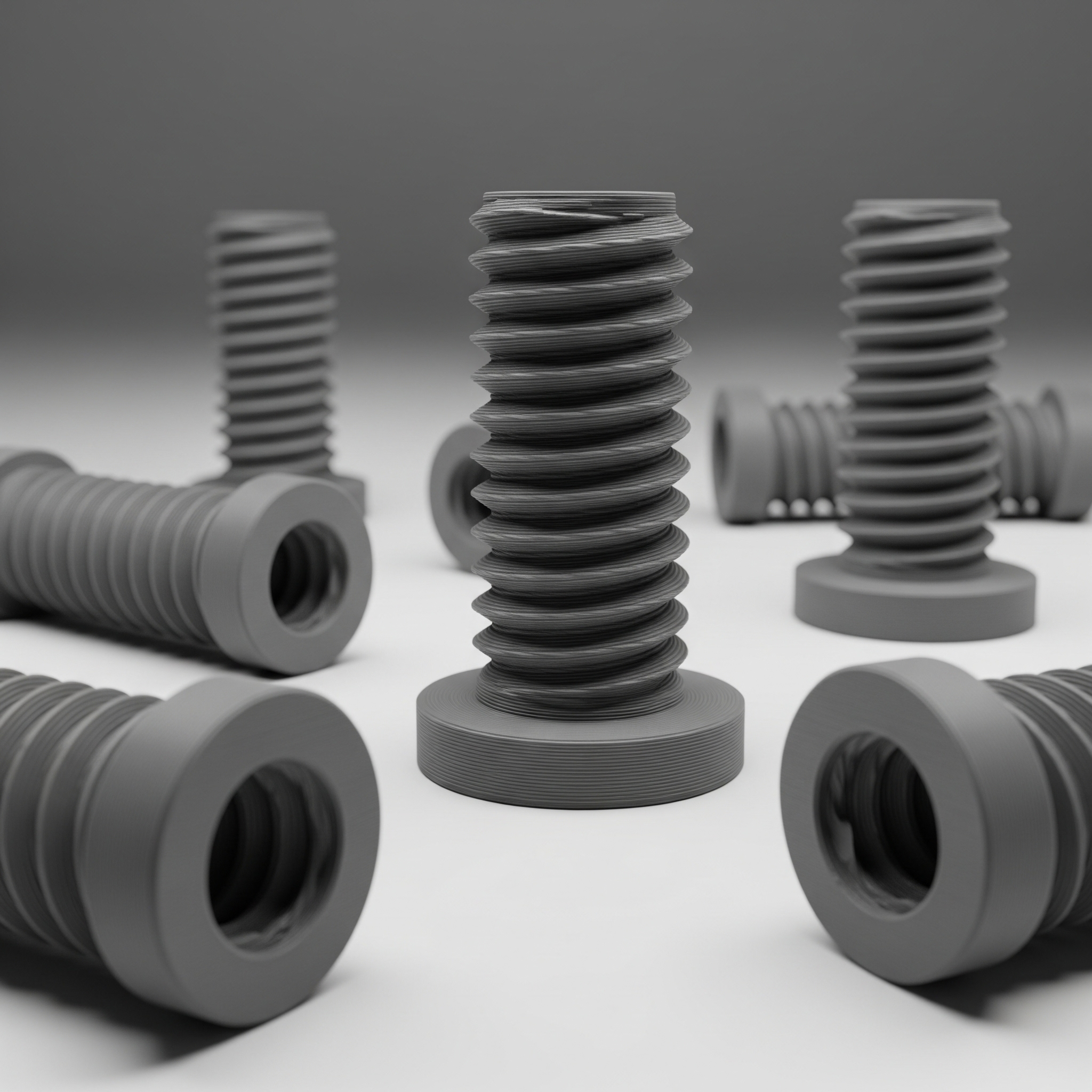

In the FDM process, plastic filament is heated and deposited layer by layer to build a sturdy part. This method is ideal for quickly and affordably producing functional components, models, and technical aids.

Thanks to a wide range of materials — from PLA and ABS to engineering plastics like PC, nylon, or carbon-fiber reinforced filament — FDM is incredibly flexible and versatile.