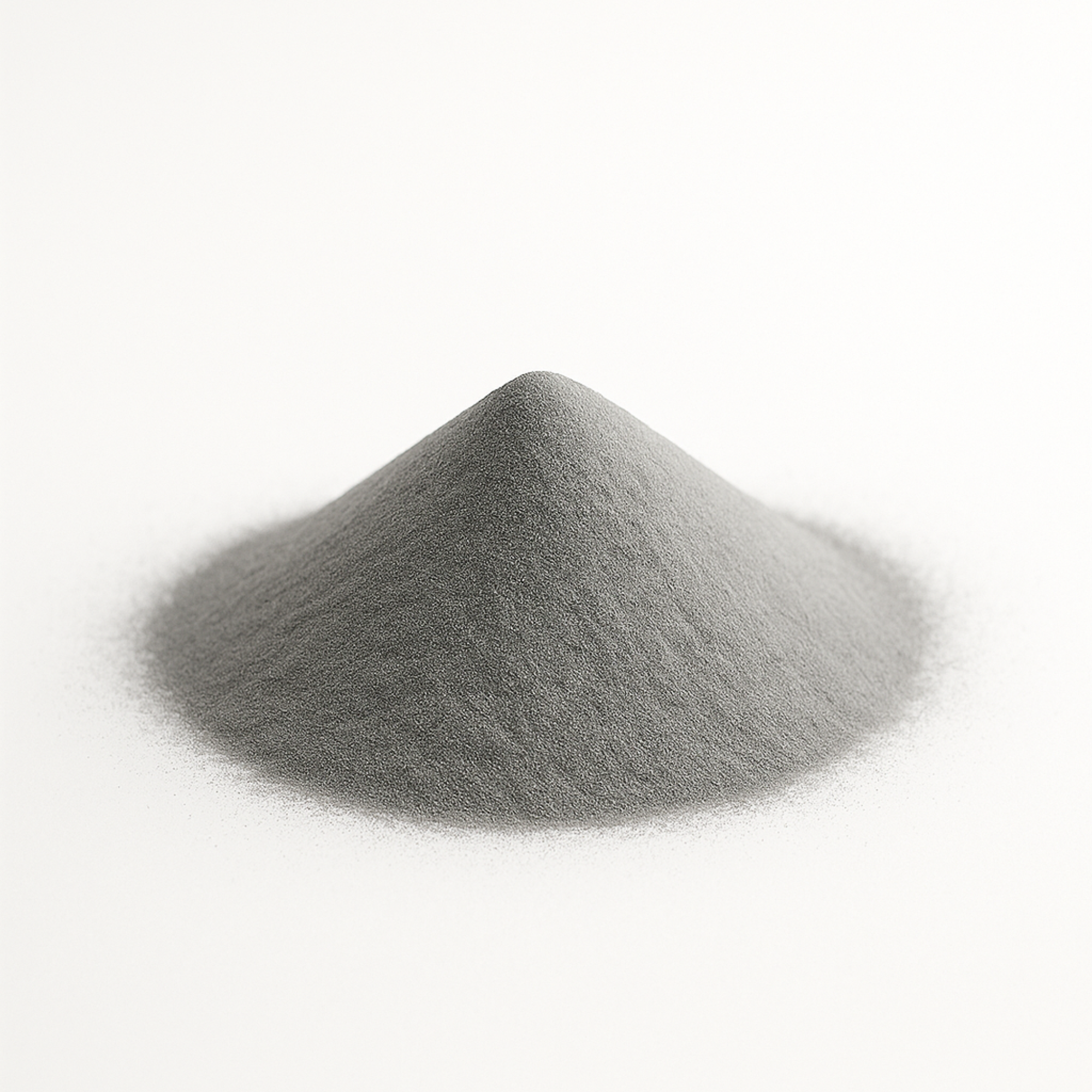

SLM Material Stainless Steel 316L is a corrosion-resistant austenitic stainless steel known for its biocompatibility and mechanical durability. This material is ideal for complex part geometries in aggressive environments, such as medical technology or the chemical industry. Thanks to its good weldability and processability, 316L is an excellent choice for both functional prototypes and series production parts.

Request your custom quote now.

Advantages:

-

Corrosion-resistant, including against chlorides

-

Suitable for prolonged contact with food and bodily fluids

-

Excellent mechanical properties

-

Precise, smooth surface finishes achievable

Typical applications:

-

Surgical instruments and implant components

-

Pumps, valves, and pipes for chemical processes

-

High-load housings and machine parts

-

Decorative architectural components