Our 3D Printing Methods – An Overview

Our 3D Printing Capabilities

With our versatile range of equipment, we cover a wide spectrum of 3D printing technologies – from high-precision production of small components to large-format prints. Whether prototypes, functional parts, or small series: we offer the right solution for a variety of requirements. Below you’ll find an overview of the processes we offer, along with the maximum build volumes for each.

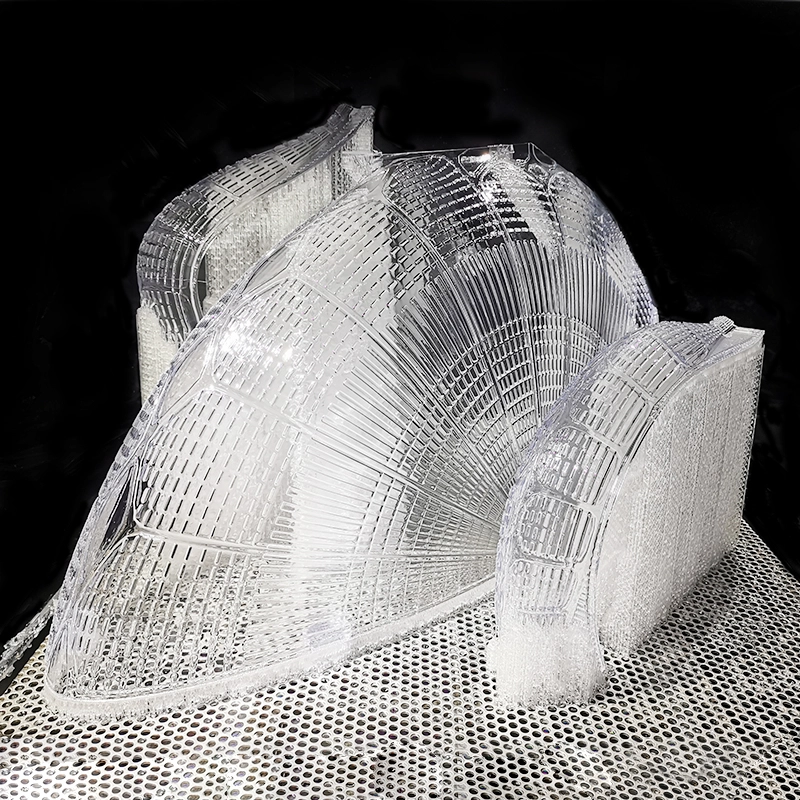

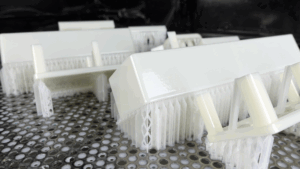

SLA Process

Extremely detailed 3D printing with smooth surfaces. Ideal for prototypes, dental models, and design objects.

Max. build volume (mm): 1000 x 1000 x 600

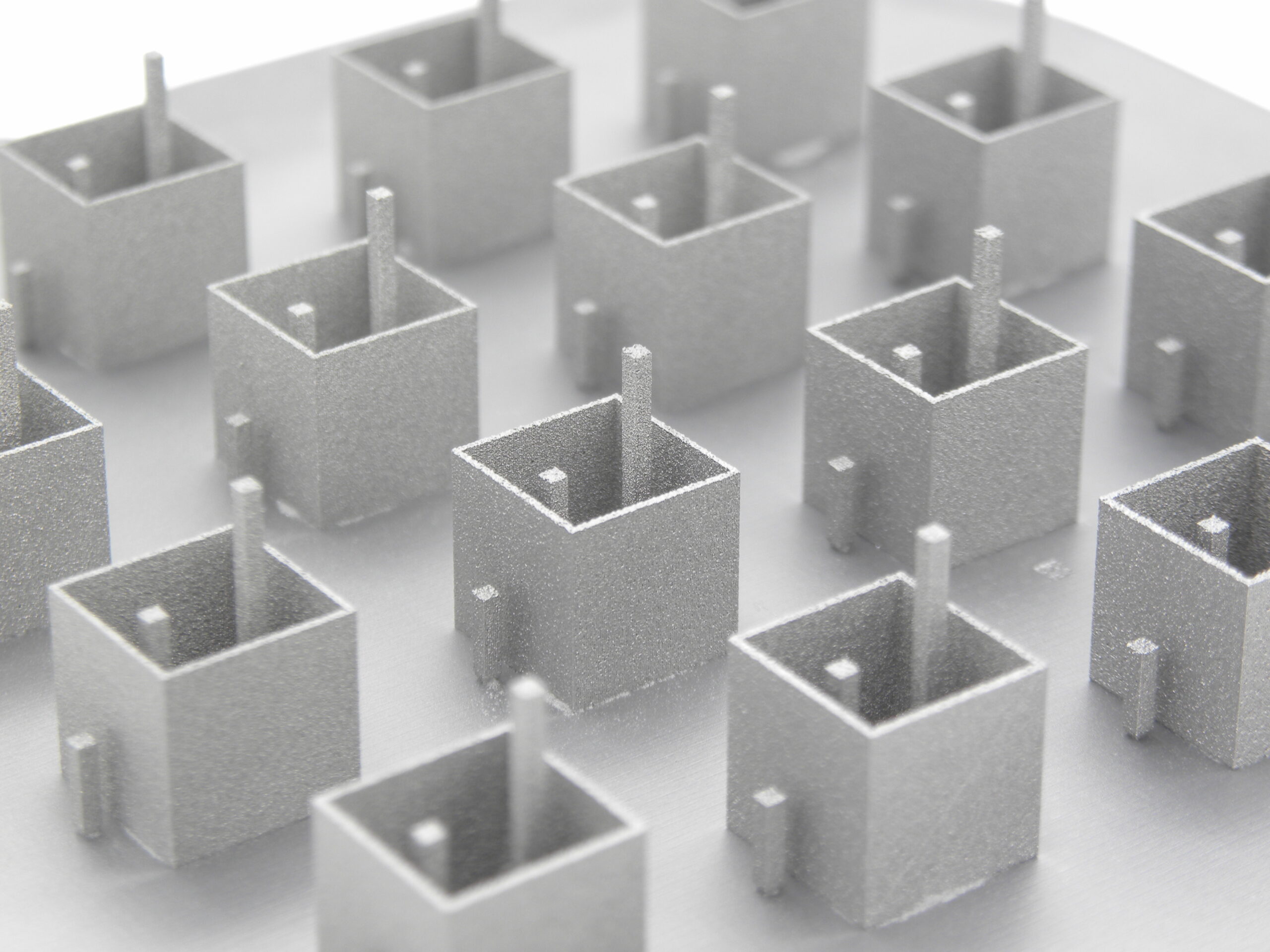

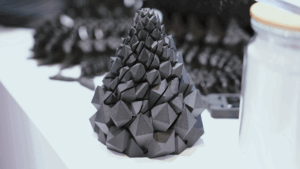

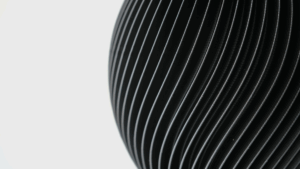

Request SLA PrintingSLS Process

Functional plastic parts without support structures. Ideal for robust prototypes, series production, and technical applications.

Max. build volume (mm): 440 x 440 x 450

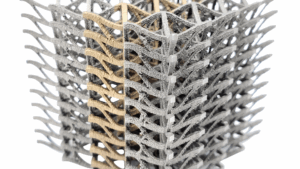

Request SLS PrintingSLM Process

High-precision metal printing for demanding applications. Components made from stainless steel, titanium, aluminum, and more.

Max. build volume (mm): 480 x 320 x 300

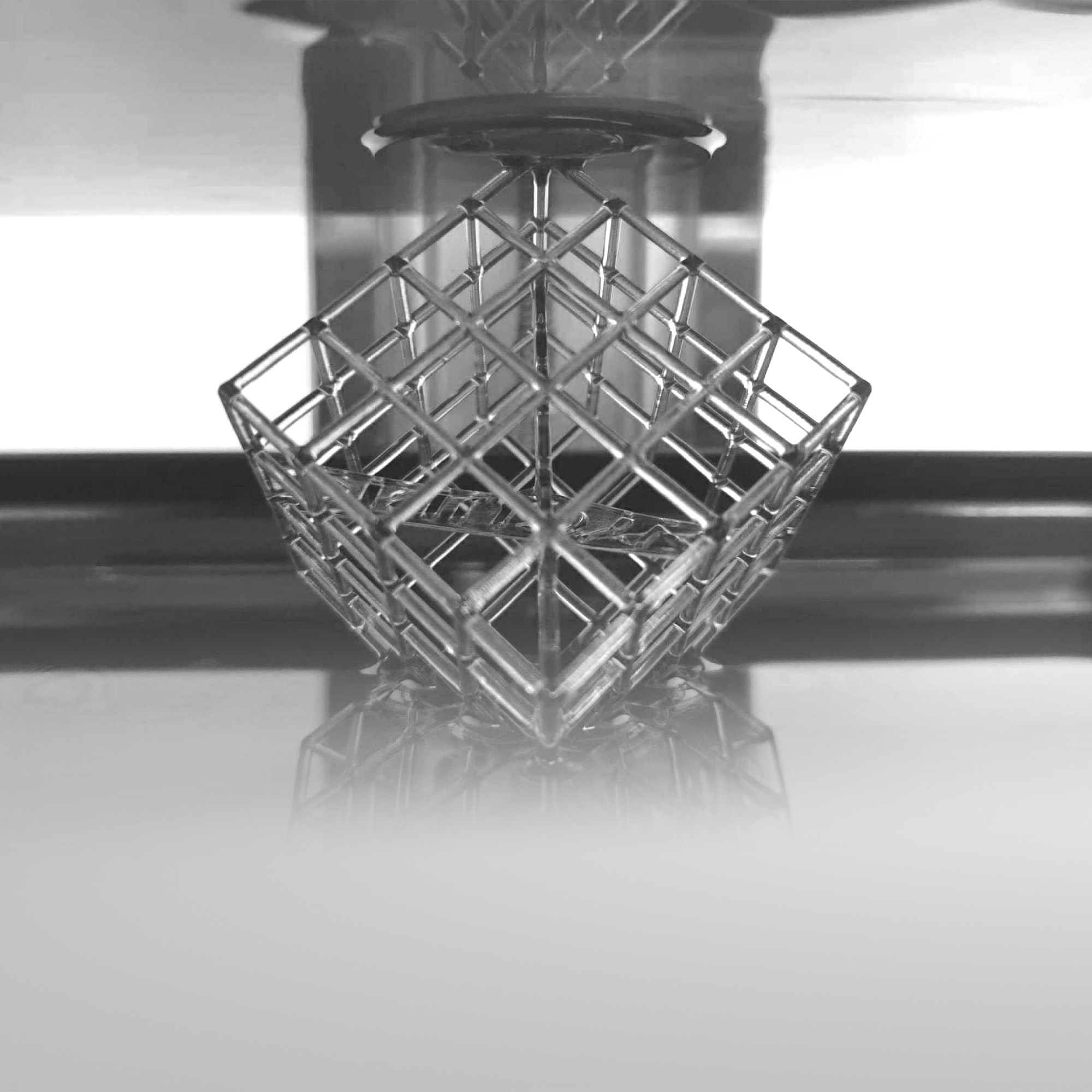

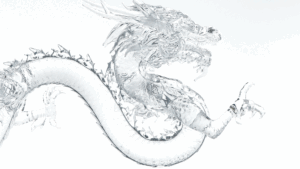

Request SLM PrintingDLP Process

Fast resin printing with high precision thanks to area-wide light projection. Perfect for miniatures, jewelry, and dental applications.

Max. build volume (mm): 295 x 164 x 300

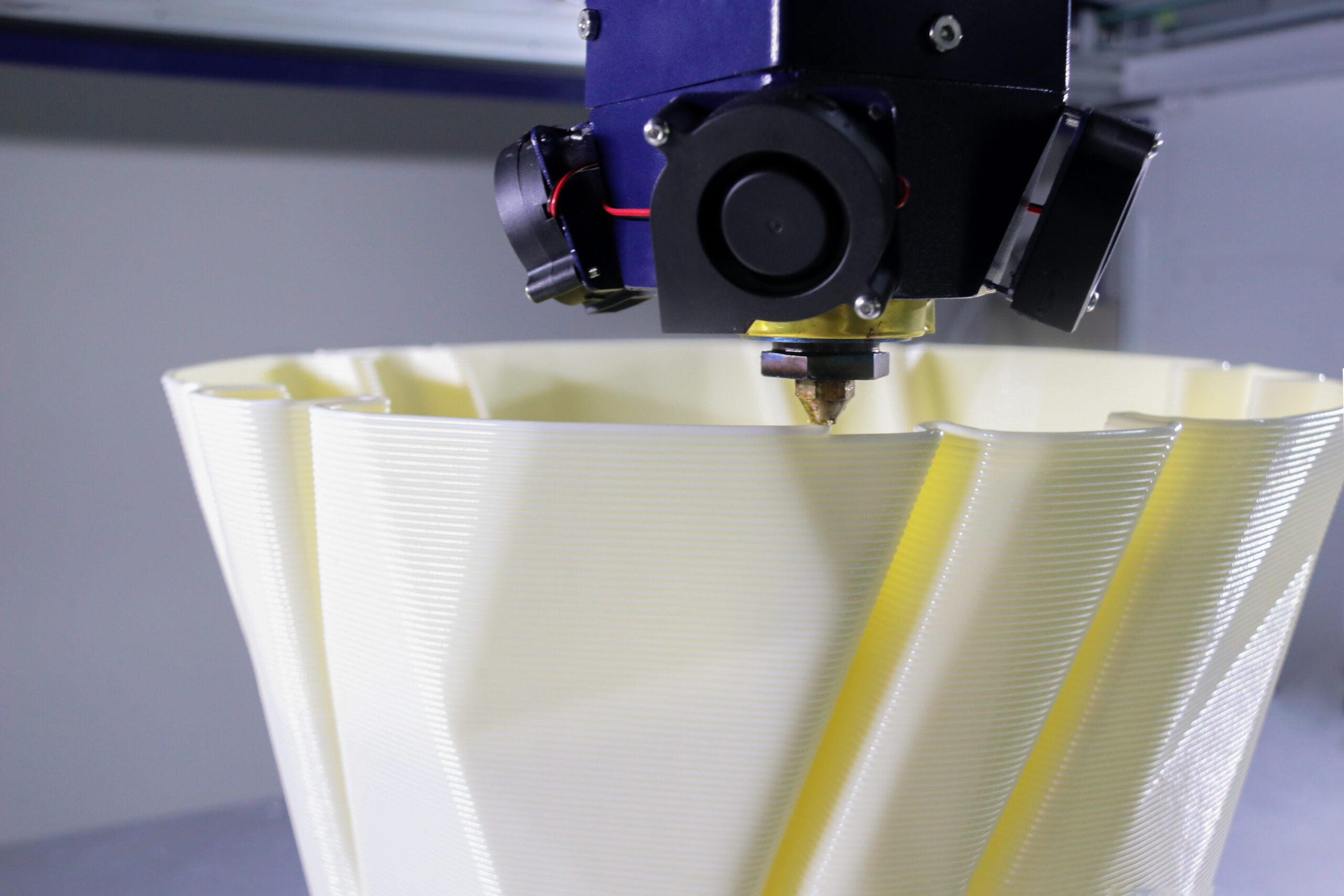

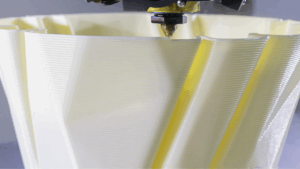

Request DLP PrintingFDM Process

The proven all-rounder among 3D printing methods. Cost-effective, durable, and ideal for prototypes, tooling, and small batch production.

Max. build volume (mm): 400 x 400 x 500

Request FDM PrintingFGF Process

Large-format 3D printing directly from granules. Fast, efficient, and ideal for molds, furniture, components, and more.

Max. build volume (mm): 1800 x 1300 x 1300

Request FGF PrintingComparison of 3D Printing Technologies

SLA, SLS, SLM, DLP, FDM, and FGF: These technologies differ in their applications, maximum build size, need for support structures, mechanical strength, surface finish, suitability for transparent materials, and post-processing requirements.